spassmaker

Forum Replies Created

- AuthorPosts

-

Hi

First, F1 is blown because D20 was shot.

D20 is a protection Z diode wich makes a short circurit to ground when the voltage rises above e.g. 6,3 volt to protect the uPC.

I’m not really sure but for me it looks like the reset IC1 PIN39 should have low level.

I would recheck TR17 and C20 and D15.

Maybe member Dillen has a suggestion about the reset state at IC1.

BTW:

Did you recap the Beogram or did you resolder the solderjoints of all plugs so far?

Lot of trouble comes from these failured caps and dry solderjoints.

Kind regards

Christian

Hi

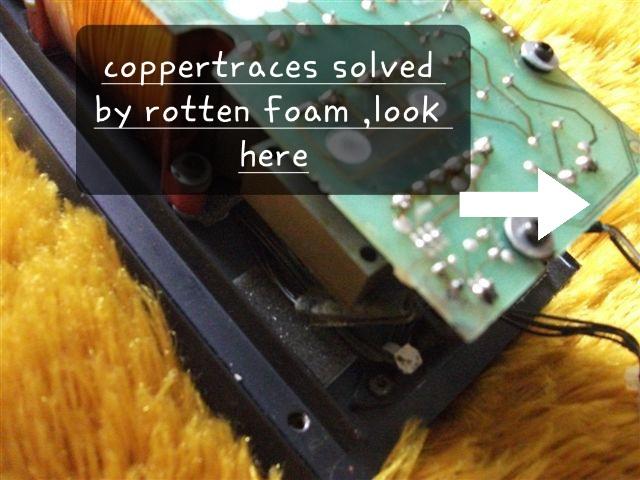

The problems you discribed are mostely caused by the rotten foam inside the speakers.

There is a PCb in the lower section of the speaker with the relay circurit, the most lower copper traces can be solved by the rotten foam and must be renewed with e.g. some wire soldered to the start and end solderjoints.

Further information about disassembling you can find here:

Look for these traces:

Any questions? let us know.

Kind regards

Christian

As I already wrote, the speakers sounding absoloutely amazing.

Far different from the M 150 of course more deep bass.

Have the MC 120.2 in another room, did never expect such a good fundamental sound, missing nothing.

Next day I hope to compare with my Nubert Nuline 102. It´s not a real comparison 😉

Now it´s time to say goodby to my 5.1 set and switch back to stereo with Beomaster 8000, Beogram 8000, Beocord 9000, Beovox MS150.2 and a MC 40 cabinet.

Maybe I connect a pair of CX 100 to the secondary speakeroutlets to have a “rear speaker”.

Have a nice week

Christian

Hi

What I would do is to open the amp again and have a close look where the tabs should go.

Maybe a part of the wireharmes in the way.

The shielding plate over the uPC is in it´s place and all the way down? All metaltabs of the plate are outside?

You could stand the amp like an open book on it´s side so you can better see and feel what going on.

Put somthing under the amp to not damage the wooden frame.

Usualy push from below in direction of the display and push down the lower edge and let it snap in.

Regards

Christian

Hi, here are some news…

I cleaned the wood with a magic eraser and a light soaped water with a neutral soap.

After letting it dry I put some renovating oil on the wood and let it shine again.

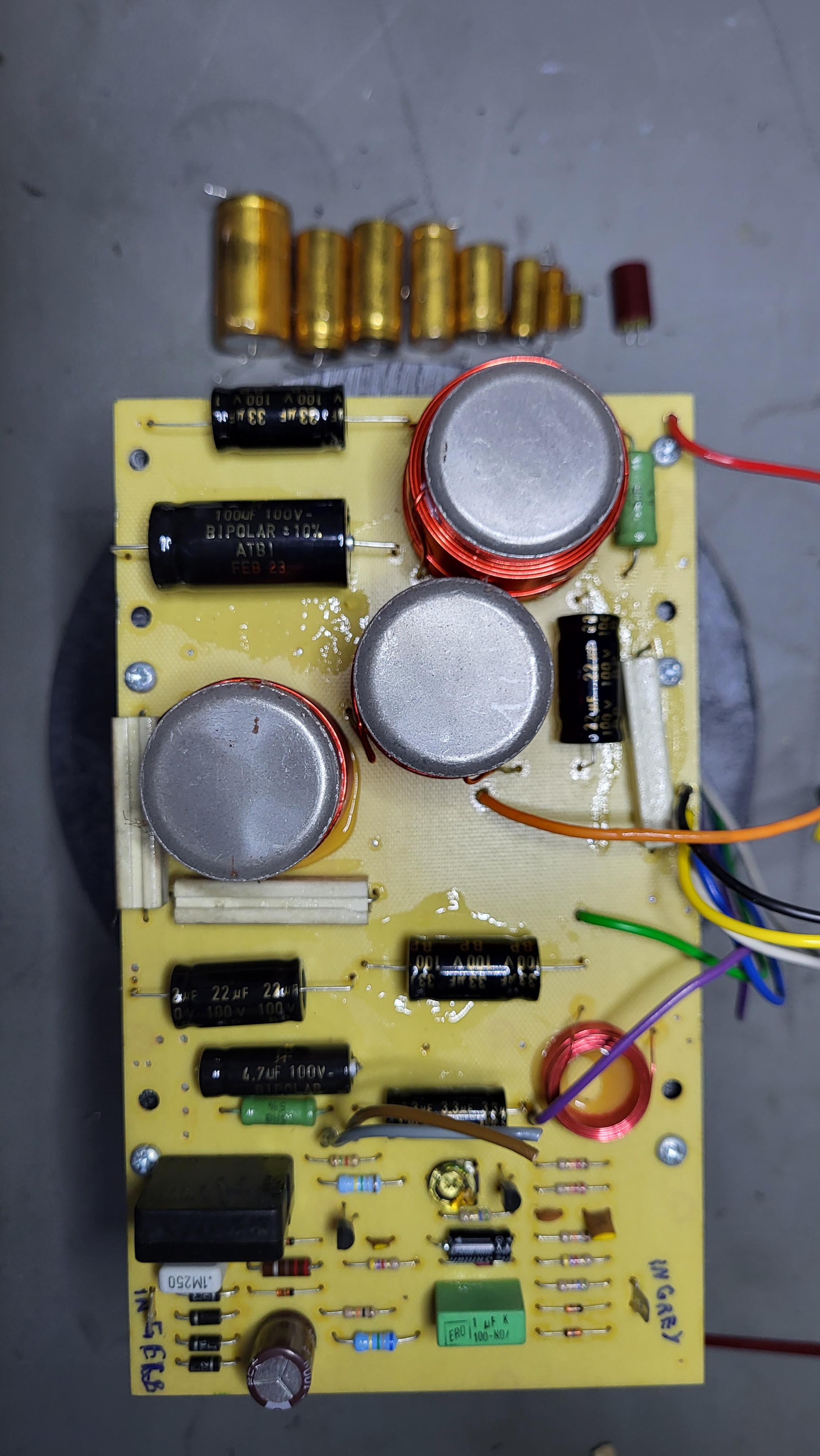

I recapped the Crossover network with new bipolar caps, just business as usual, old ones out new ones in.

After that I assembled the chassis into the front frame and made the wireconnections to the speakers.

Mounted the frame to the speakers and made a testride.

Wow that sounds absolutly amaizing.

Here is the not really finished speaker, fabric was not delivered today 😉

Hi

Yesterday the foam surround from “Good Old HiFi” NL arrived.

So I started to refoam the 4 woofers.

First I started with the 8″ woofer, cleaned the cast frame and carefully sraped the old glue from the plastic cone. My favorite solvent Mellerud glue remover made a good job.

Before:

After:

After cleaning I glued the foamsurround as much possible centered to the cone. I’ve made a marking arround the cone to see how far the glue should be painted. Put the glue to the backside of the inner foam let it dry for about 5 minutes and pressed it firmly to the cone.

After that I clamped the outer foamring with clothpins to the frame and made a test with a conected amp and my mobilephone and the “Tonegenerator” app at 25 up to 50 Hz to hear if the voicecoil is aligned an centered. No adjustments where requiered. The 8″ woofers need no chimming in my case and I glued the foam to the cast frame. You could see on the last picture.

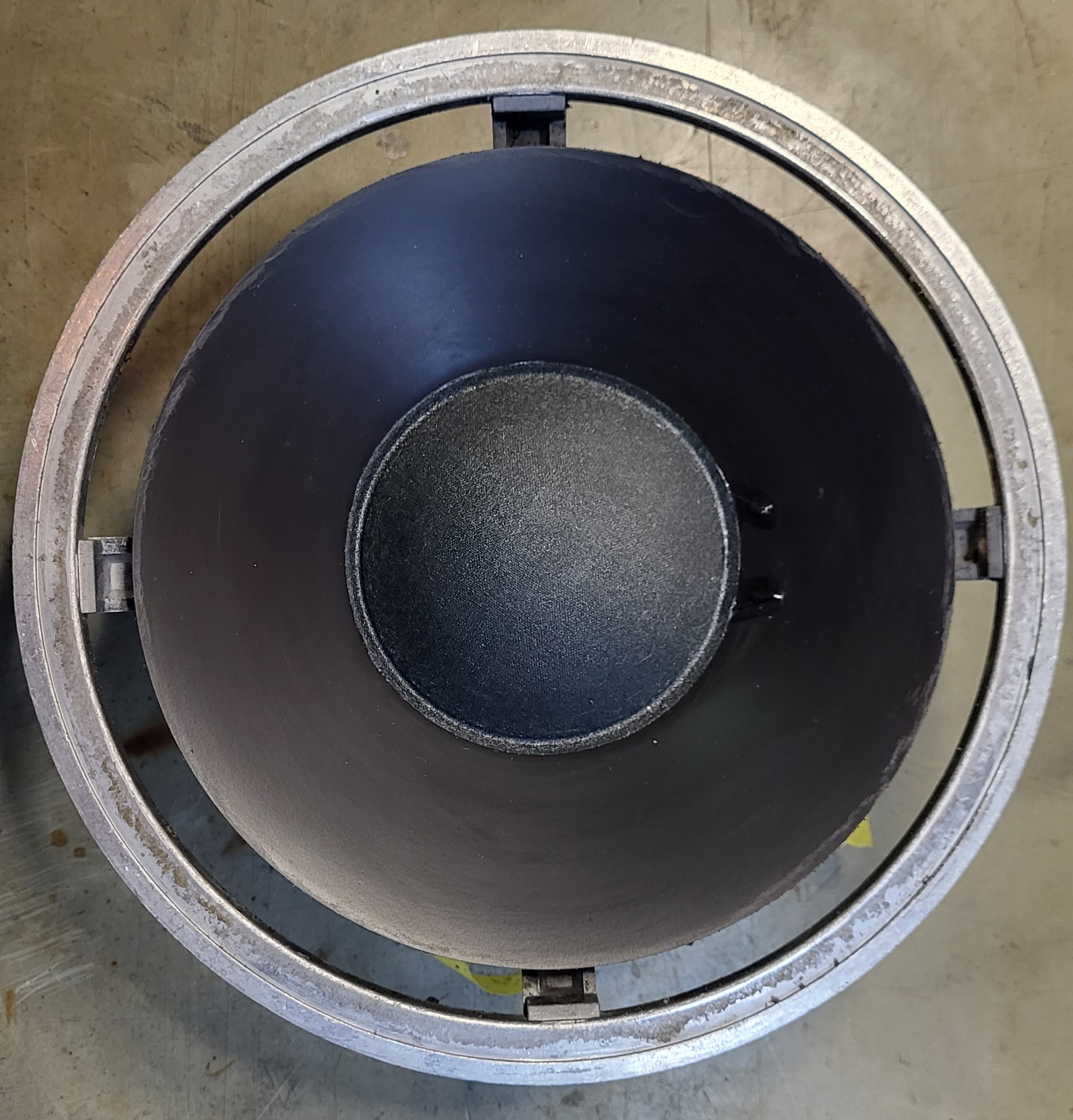

Up to the 10″ woofer.

I started with glueremover very carefully only on the old rotten glue because the cone is made of paper and I would not to get to much moisture into the paper.

After about 10 minutes I could peel off the old glue with my fingernail. There is a minimal layer of paper wich comes off with the old glue but that’s no problem.

As you cn see there is a damage left from the stick wich was mentioned in the first post. The new foam surround covers exactly thes damages so I’m happy. ;-))

Next was the same steps as the 8″ woofer, I glued the foam to the cone , tested with clothpins and made a marking around the outer foam to know where the foam has to be glued on the frame.

The cone centered itself like the 8″ woofer, no alignement nessesary.

Here is the result: cheers;-))

Complete set of woofers after 5 hours:

Thanks for watching!

Next is the renew of the fabric grilles, new capacitors on the filterboard and refreshing the wooden case.

Kind regards

Christian

Hi

In between I dissassembled the 8″ and 10″ woofers from the cabinet.

The coils are measuring all good so far.

I decided to bring them back in shape as following:

Took some aluminium profiles 10X10 mm and put them underneath the cone to lift the cone upards about 1 cm above the metal frame.

Sprayed with a small amount of water front and back of the cone and let them laying cone downwards on the table over night.

The weight of the chassis gave the right amount of pressure to the cones and next day it looked very good for me.

on the picture you could see the result.

Does anybuddy have a good source for the front fabric? Mine have some small holes and not looking good anymore.

Still a little bit dirty but that will be no problem so far ;-))

Waiting for the foam surrounds…..

Kind regards

Christian

Hi

Thank you for the helpful hints.

For me it looks like the stick has left two dents in the paper cone while it was there for several years and I’m not sure how to bring the cone back to shape, maybe with hot steam.

I will take out the speaker next days, foam surrounds are already ordered.

I give more information after that.

Regards

Christian

Hi

Looks like the Beogram and the Beocord need some restoring.

Beogram: All capacitators, resoldering of contacts and adjusting the << >> buttons, new tangential drive belt.

Beocord: Most all capacitators and cleaning the cassette drive mechanism, new belts.

Ask for someone near you who has some experience with B&O gear.

Regards

Christian

Hi Alf

Maybe you let all others know how you managed the deal with the stepped pulley.

regards

Christian

March 17, 2023 at 9:00 am in reply to: After Recap Kit done, still a CD problem Beocenter 9000 #17585Hi

Normaly the CD shold work with the new caps. Recheck the polarity of C 2103.

Maybe you have to readjust the laser current.

Could not find how to in the Beocenter 9000 SM but similar in the Beocenter 9500 SM page 5 14.

On page 5 13 you’ll find the points where to connect the DVM. Measure 50 mV and adjust with R 3106.

Carefully turn the pot, the current changes quick in both directions.

Kind regards

Christian

Congrats!

“WISE GUY MOD ON”:

When you used shrinking tube at the reservoir caps, why did you not put it over the soldering?

It’s a 4700 uF, keeps a lot of power inside when you touch chassis ZAPP!, don’t ask me why I know ;-))

I’m missing the clamp for the cap, maybe with some feltpad underneath to get it tight fit.

I would have mounted new pots on the mainboard while I have the unit already open. The speed trimmers could be precize spindle trimmers so it’s easy to get the right speed at 33/44.

“WISE GUY MOD OFF”

Kind regards

Christian

Hi

When you try to set the idle current measure the voltage at the speaker outlet

(speaker switched ON 😉 ) or L201 on power amp board.

Look for DC voltage more than 0.1 Volt.

Often had this issue, look if you get any variations when you try to adjust the OFFSET Voltage with R210. If not adjustable check TR201 to 205, best to desolder them because some of them are connected in paralel.

Seems that when you are through with this BM 6000 you can call yourself

CEFBM 6000 (certified expert for Beomaster 6000 issues ;-))

Regards

Christian

Hi

This is what I found in the old forum:

https://archivedforum.beoworld.co.uk/forums/t/35376.aspx?PageIndex=1

Lot of information some pictures of the way the string goes.

Regards

Christian

Hi Luke

At first I would replache the CMOS battery, often makes problems. Even the other board works, could be working on the edge of battery life…costs not a big deal.

Second I would ask member Beobuddy for help, he’s able to write new eproms.

Regards

Christian

Hi

The problem with the keyboard could be a issue with IC 5 (STROBE) or the railvoltage for transistors T15 – 19 and TR 22. Look here for C 49 (1000uF)

These transistors should ” amplify” the strobe signal from IC 5, go to the LED displays and via resistors R3 – 8 to the keyboard.

The strobe signal is fed via the keyboard to the uPC IC 4 PINs 8 – 12

If there is no strobe signal present the keyboard won’t work.

Regards

Christian

Hi

Check all connections, pull out and reseat the DIN plugs.

Cracking on all sources?

Tuner too?

Switch connection CD to Tape input.

If present, hook a mobile MP3 player with an 3,5 mm to DIN jack to the eg. Tape input.

Please let us know what kind of speaker are connected (aktive via Powerlink or passive)

Common problem with e.g Beolab 4000 MKII is a crackling noise caused by a dieing ICE Power amp module.

Regards

Christian

Hi

From the distance it’s hard to sort out what the cause of the amps problem is.

Look for the service manual and start measuring the basic voltages comming from the power supply board.

Often the Beomaster 6000 came back to life when renewed the caps on this board, can happen, must not.

If this did not help it seems that you have to recap the complete amp including the poweramp section. There are new precise trimmers for the idle current and offset highly recommended.

I’m not shure what happens if you pull the plugs from the keyboard and try to switch on with your terminal remote, never tested this.

you should be a skilled hobbyist to perform these working on the amp, no work for “two left hands” ;-))

Kind regards

Christian

Thanks for information

Now everything is clear.

Hi Stephane

Never thought that this IC could be the reason , lesson learned.

Could you discribe what the cause of the problem was, e.g. PIN 21 CLP or PIN 22 SER DATA to ground? something like that?

Regards

Christian

- AuthorPosts