KolfMAKER

Forum Replies Created

- AuthorPosts

-

So here’s an additional question …

Is it possible to simultaneously:

- Connect a turn-table via the Auxiliary Pin 3 & 5 and play vinyl

- And connect my cassette-deck via the same Auxiliary Pin 2 & 4 and record the music from the turn-table

Is this possible?

(Assuming of course that a made a splitter cable which can handle that)

Thnx to all, this is a great experience to have such great responses so quickly on the BeoWorld forum!

Additionally I should mention, the external recorder is non-B&O. It will be a vintage Nakamichi 600 cassette deck.

Not being able to control this external recorder as a B&O device is not an issue. For me it is just important that there is a L & R channel OUT, that I can pick up via the Auxiliary connector on the back of the BeoSound 3200.

So from all your information I conclude it is possible and will work. As long as I use:

- Pin 1 > Left out

- Pin 2 > GND

- Pin 4 > Right out

As mentioned and described in the response and picture of Matador.

Thanks!

Hi Cavscout,

How sure are you that the leads in your cable(s) are connected to the right pins?

Do you have a scheme of the connections, and where did you buy them? (Did you contact Steven from SoundsHeavely?)Thanks for your extensive response and guidance. This is very helpful!

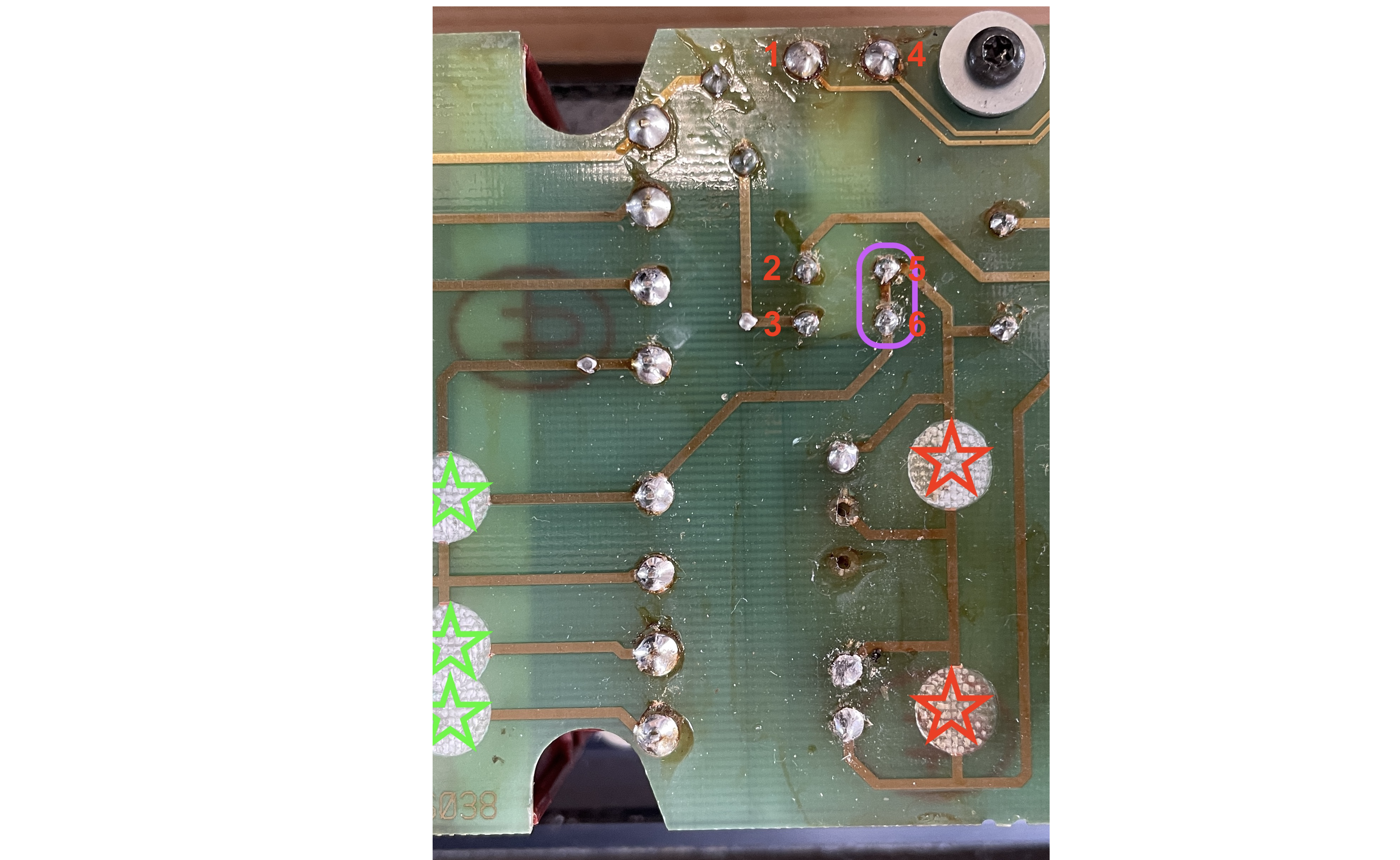

Some clarification questions from my side.- For checking the 23v DC at the relay coil … I believe it has 6 pins. Which ones should I use to measure on?

- You mentioned it possible for the Relay RL1 to stick open. What should I (not) measure when it is stick open? And at which pins should I do the measurement?

For reference, I added a picture showing the bottom of the PCB and the relay pins with numbers.

It’s gonna be stereo to mono.

In this case I am not going to link two speakers to a stereo set.@Pilatomic: thnx!

In the meantime I ordered the Taco TMR 4-4811WI, and I have been able to make a test setup with all connected. This is what happens.

When I turn the system on:

- C5 +/- measure 35v, so that’s fine.

- The Taco output measures +/- 5v, so also fine.

Which means, when I plug in power on the BeoLab 6000, my wireless module gets 5v, and starts booting. Streaming music also works fine after the booting.

Problem

When I stop streaming music, the BeoLab switches back to stand-by (Green LED becomes Red).

But at that moment, the voltage coming from C5, drops from 35v to 30v. This causes the wireless module to reboot, which causes the auto stand-by switch back on (Red LED becomes Green).

Which means, this situation creates a loop. Every time music is stopped, the BeoLab returns to stand-by, which causes voltage drop and the wireless module to reboot, …. and so on.

Question

Maybe C5 is not the right point to take the voltage from.

- Is there any other point where the DC voltage is always available (also in stand-by mode (Red LED), and in a constant voltage?

- Where?

Thnx Matador!

Concerning your PSU suggestion …

This is how I started, but I have had some issues with it. Adding a AC/DC converter that connects to the same power source as the BeoLoab 6000 itself, can cause disturbed audio signals. Many AC/DC converters work, but because they are switching PSU’s, they can cause ‘Ripple’ disturbances.

Therefor, I think an added wireless module can better be powered with DC voltage from the BeoLab 6000 system. This will be much cleaner.

Can you help me understand where such DC points on the PCB can be found, or do you know someone who can?

@Damiendada

Do you mean, you are also looking for voltage points?

So if I understand right, you put an MK2 amp in a MK1 housing right?

I assume you took the old foam out and that you had to clean the remains from foam rot?

If that is the case, you can check if some of the copper traces on the PSU PCB have been damaged by the foam rot. Sometimes you need a magnifying glas to see it, but then you might detect copper traces partly ‘eaten away’ by foam rot. If you have such a thing, you can solder a wire as a kind of by-pass.

Also check if there is still foam rot remains on connectors or components. And check if there are components that are damaged, like for instance capacitors that look puffy.

What is the serial number / production year?

Thnx Matador!

I am gonna use a small external Bt-antenna. Wire goes external via bottom to foot plate.But can you help find a DC voltage in the BeoLab 6000 that would work for me?

Dear Warrima,

What brand and type of CD player did you connect to the BeoSound?

Well I can only say that I have made a custom cable (mini-jack > DIN), that connects to the right pins of the MasterLink connection on the BeoLab 3500.

Since what I connect, is not a B&O device, the MasterLink will not automatically ‘sense’ that an audio source wants to play via this connection.

So to activate the MasterLink as an audio input, I use the BeoLink remote to switch to the ML-input, by pressing this sequence: “Menu > Menu > 0 > 3 > Go”The BeoLab than goes to the MasterLink input and my music plays. So everything does work, but I find the sequence one has to handle on the BeoLink, nut very user friendly. That’s why I am looking for an easier way to get the BeoLab 3500 to be activated on the ML input much easier.

- Preferably because it goes to the ML input when switched on.

- Or by pressing button to activate a kind of macro for the earlier mentioned sequence.

Any ideas, suggestions welcome again! 🙂

Thank you all for responding and for your suggestions, great!

At the moment I try to remain a bit stubborn (bear with me 😉

The BeoLab 3500 is an electronics product, which ‘boots’ when turned on. When booting it sets for the standard settings. Like for instance basic volume level, LED brightness, etc.

I assume it also sets for a standard audio source/port. So my idea (I still hope it is not a fantasy) is for instance to re-program the settings that get loaded while booting. And by that, set the DIN-connection as standard audio source to ON.Some products have the ability to change the firmware, or hack it.

I am curious if anyone has ideas about that.If you like to read into this topic, here’s an article about B&O’s ABL. It describes that ABL is not just one system, it has evolved with new speaker systems. But there’s hopefully something you will learn form it:

As far as I know, ABL was mainly developed to lift the ‘presence’ of bass in the lower volumes.

So I think that relatively seen, it does not boost bass in the higher volumes.Probably there are other forum members who know more about ABL. Please comment.

Don’t worry about de-attaching the front panels and the glue strips holding them.

Obviously, you will first have to remove all screws. After that, the glue strips will hold the speaker driver panel and the PSU/AMP panel in place. The glue strips function as gaskets.Nevertheless you can push a flat hand screw driver (actually & literally with a flat head), just underneath the panel, and push it up a bit. Do it slow, and as soon as it comes a Biot loose, move the flat head down a few centimeters, and so on.

“In the meantime do you know if not using them will slow down the process (less heat) or as this nothing to do?”

The heat inside the cabinet makes the foam deform. As Long as you do not use them, the process will of foam rot will not continue. Be aware though that the damage might already have been done. Some times, some of the copper tracks on the PSU PCB are eaten away. And sometimes that’s even hard to see with the eye. But this is easy to solve with some by-pass wires.

Hi Matador,

Foam rot is a serious thing as it can damage the pcb and electronics, causing malfunction, etc.

I am not completely sure about which serial number has the improved foam, but I think 12xx xxxx might still have the old foam.

My advise for proper action is not to apply self cut pieces of plastic. This will not help, because when foam rot is there, it is already damaging the pcb and components. The only way is removing the old foam and thoroughly cleaning the pcb and components.

Great & excited!

Thanks very much for this suggestion Christian. Very helpful to know!

At the moment, I am quite sure I will be able to get the mid-tone driver alive and well again. So I will proceed to find the appropriate glue for attaching the dome back to the tape on the metal ring of the mid-tone driver.

If you have an advice about the right type of glue, I am open to hear.

- AuthorPosts