jfrancis49

Forum Replies Created

- AuthorPosts

- February 4, 2024 at 7:56 pm in reply to: Beogram 4002 Solenoid Engages When Power Cord Plugged In #29420

Thanks Martin!

February 4, 2024 at 4:34 pm in reply to: Beogram 4002 Solenoid Engages When Power Cord Plugged In #29416Thanks for the suggestion Martin. Just to be clear are you referring to IC2?

John

December 29, 2023 at 8:05 pm in reply to: Bepgram 4004 – tone arm doesn’t proceed – stop button doesn’t work #27894Hello Luigi,

If this turntable has not been used for sometime it probably needs at the least be cleaned and lubricated. As you know these are not simple machines and depending on your skill level you may need someone to do someone familiar with servicing it. There is a service manual you can download from this site that can be of help for many tonearm and servo tracking adjustments after cleaning and lubricating. The keypad has copper contacts that may be oxidized and causing your stop key function. If you take the keypad out it can be cleaned by inserting a small strip of sandpaper between the contacts. Ideally the sensor arm should be removed and the tone arm linkage cleaned and lubricated.

If you have not had a capacitor replacement, that needs to be done as well, look up Beoparts on the web to see if they can help. There are electronic faults that unless you have experience with electronics will not be solved by cleaning, lubricating or adjustment.

I am not an electronics technician. These are great turntables but take it from someone who basically can solder and follow guidance from a lot more experienced people on this website, there are a lot of things to sort out before a simple answer can be given to your turntable issues. But maybe one of the more experienced people here will give you a more specific solution to your problems.

Good luck.

John

Just in case you meant tracking force for a record, 1.2 grams is a good starting place. Different cartridges have different recommended tracking forces.

John

Thanks to all of you for the advice and feedback. I went ahead and placed the capacitor according to the spare parts board, I think that placement was consistent with Martin’s advice. I had some confusion tracing the circuit.

The receiver is now working, and I am not connecting a turntable to it anyway so maybe the polarity is immaterial.

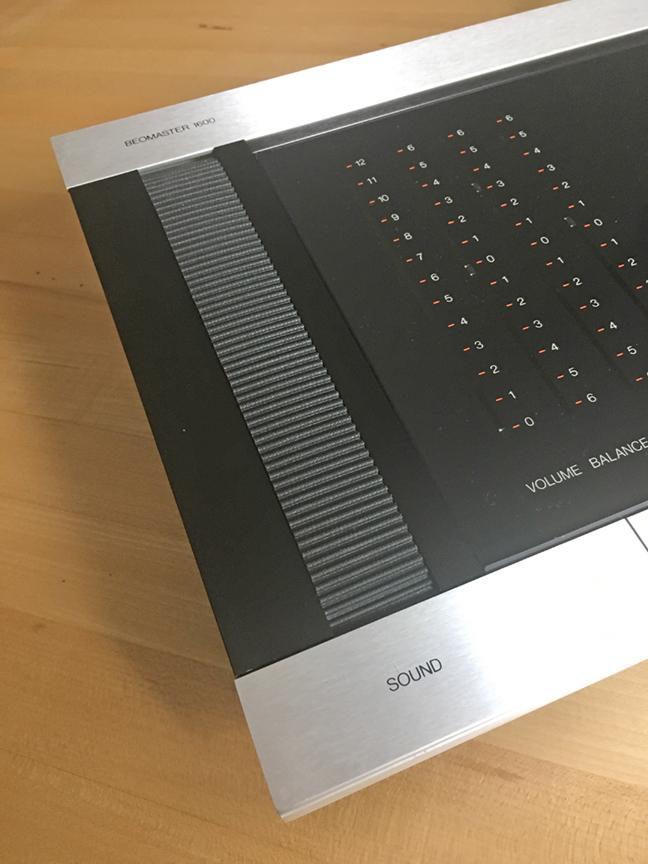

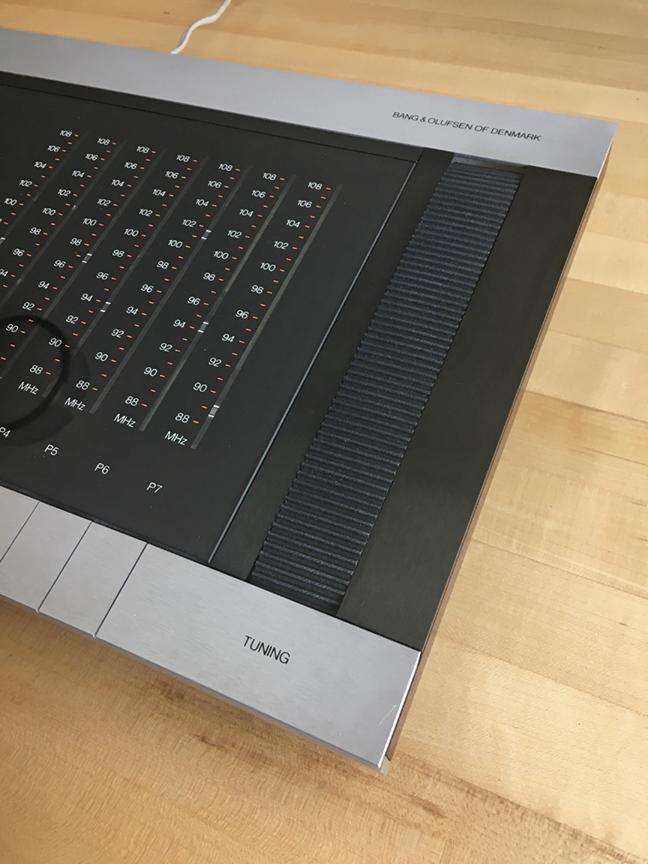

Not an audiophile receiver as Martin pointed out, but a nice unit to have as a secondary sound system.

Happy Holdays!

Sorry to sound so dense, but can someone tell me if the positive polarity of C110 is then correctly connected to R110 as is on the parts board?

Thanks!

Hello Martin,

I am hopefully tracing from TR100/R111 correctly and the circuit goes through R110 to C110. I have your capacitor replacement kit for the 1600 and the photo for that looks like the positive end of C110 goes to the outside of the board. It is the capacitor that is furthest top right and is 2.2uf. Does that sound correct?

Ps. Thanks Glitch!

Thank you Martin, that was very helpful!

John

Thanks for that Martin. Does it matter with the grey power wires which goes right or left?

John

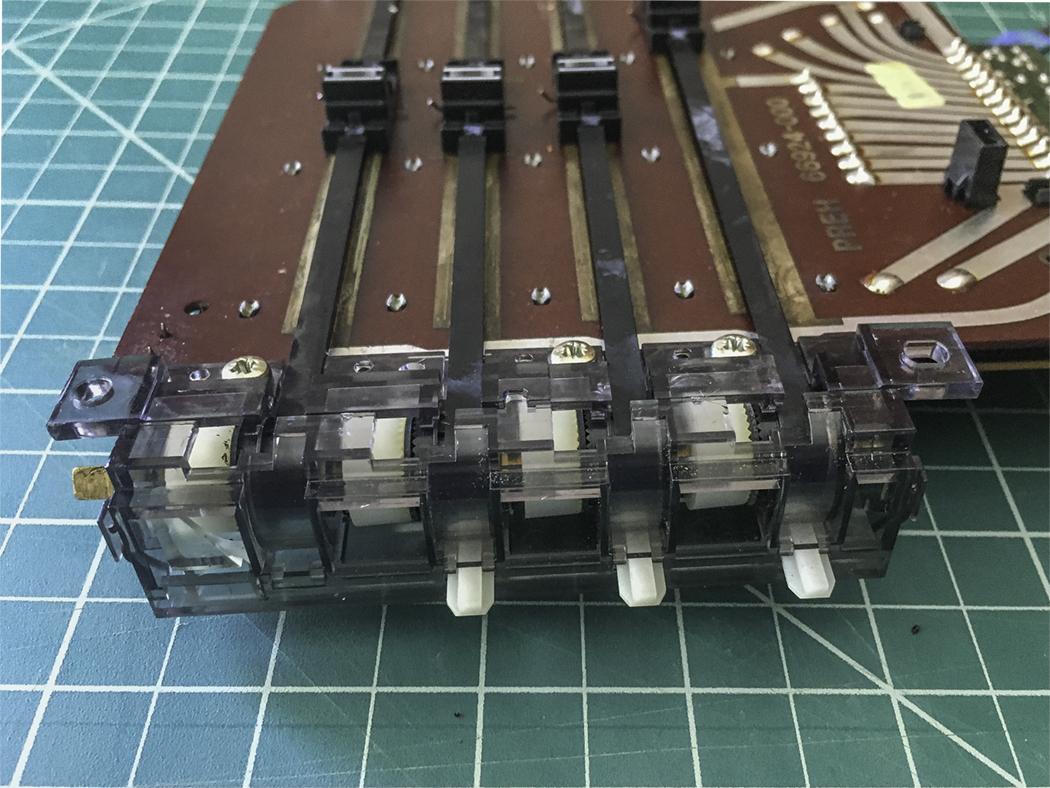

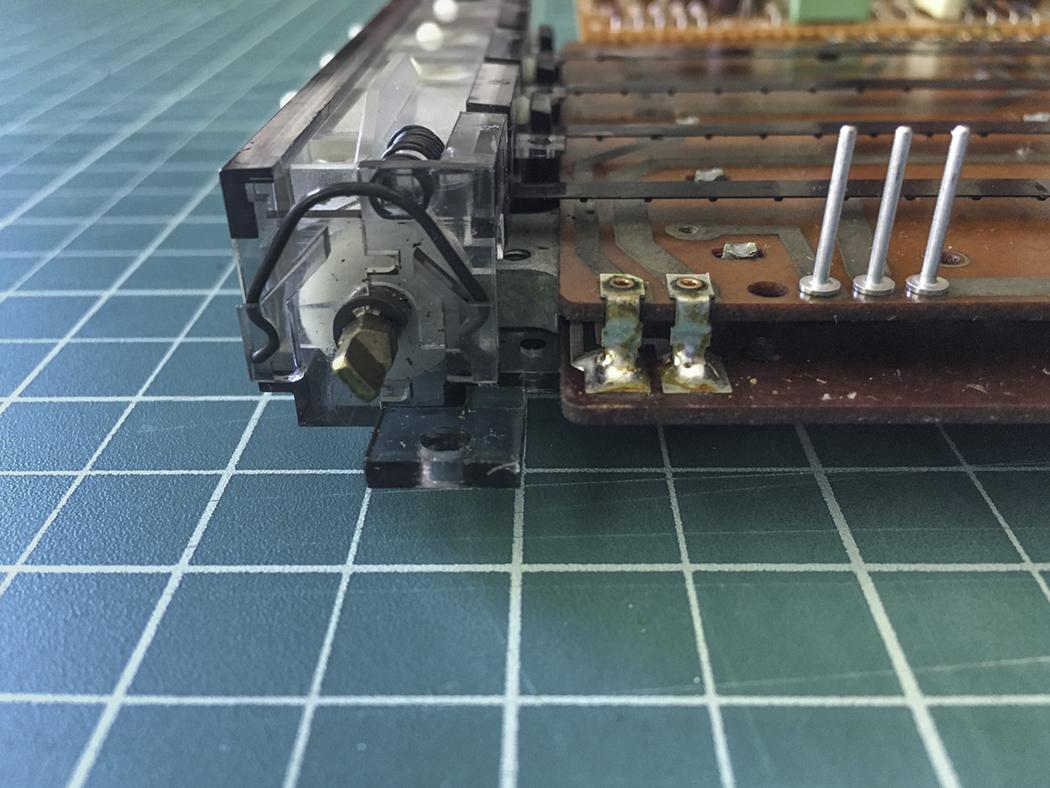

Here are images of the belts I made. The idea of 3D printing belts sounds like an interesting one. I don’t have that skill at this point or the equipment. Maybe someone else might take on that challenge.

John

Hello Tomas,

It is probably not likely you are going to find easily find original B & O replacement belts in good condition for the 1700/1600 receiver. After a long time of searching I did find a source for making my own replacement belts. The belt is not the exact width and needs to be trimmed down and spliced to make it a loop. But if done carefully looks better than the original and is much more durable. I would rather have the originals but that is an unlikely option.

There are different places on the internet you can find them. If you do a search for “Industrial Drive Timing Belts HTD 3M Pitch Timing Belt Width 30mm Open-Ended Transmission Synchronous Belts” you will find several sources, it is branded 3M but made most likely in China. It is available in different lengths and I would get more than you think you need. You will have to cut the 30mm to around 27-28mm width and cut the length based on an old 1600 belt. Getting a clean cut between the belt ribs for a good splice is the tricky part. That is why I would get more than I need. If done cleanly and straight you then use Gorilla Super Glue Gel and clamp it for 24 hours. I have done two belts and the seam is invisible. You can use WD-40 and a cotton swab to remove small amounts of the visible glue.

John

Also there are mechanical parts that need to be cleaned and properly lubricated that may be part of your problem.

John

Hello Karl,

I am not a real savy tech person, but until someone with more knowledge steps in I will give you my thoughts on your problem. You should at least see a light on the control panel, left side for 33 rpm if the table is getting power when you push the start button. If the capacitors have not been replaced, they probably are the first thing to go after 40 some years. There is a fuse box in the back left side under the top plates that you could check. If a fuse was blown there was probably a good reason however.

Depending on where you live, there are people who could service the table, if you have no basic soldering and electronic skills that might be the best course of action.

John

September 1, 2023 at 12:19 am in reply to: Beomaster 1600 Type 17xx Clutch Washer Replacement #23530Hello Orava,

There are different places on the internet you can find them, I am not sure the moderators want us to post sources. But if you do a search for “Industrial Drive Timing Belts HTD 3M Pitch Timing Belt Width 30mm Open-Ended Transmission Synchronous Belts” you will find several sources, it is branded 3M but made most likely in China. It is available in different lengths and I would get more than you think you need. You will have to cut the 30mm to around 27-28mm width and cut the length based on an old 1600 belt. Getting a clean cut between the belt ribs for a good splice is the tricky part. That is why I would get more than I need. If done cleanly and straight you then use Gorilla Super Glue Gel and clamp it for 24 hours. I have done two belts and the seem is invisible. You can use WD-40 and a cotton swab to remove small amounts of visible glue.

I plan on posting pictures of the belts when I get the clutch washers installed. I have everything apart replaced the clutch washers, but am having issues putting the rod and parts back in the plastic housing.

John

Thanks Martin, that was a big help! I now have the left side controls taken apart.

John

Thanks for the reply Martin. I believe I understand that the couplings are the white disks shown in the photo here. But my guess is I need to disassemble this further than I have. Should I remove the screws shown in the first image and the plastic cover and the two clips that would be on each end of the clear plastic enclosure shown in the second image?

Thanks again,

John

July 26, 2023 at 11:40 pm in reply to: Beogram 4002 Tonearm Sets Down at End of Platter With No Record #22501

July 26, 2023 at 11:40 pm in reply to: Beogram 4002 Tonearm Sets Down at End of Platter With No Record #22501Thank you Mark and Sonavor! You pointed me in the right direction, it was the plastic rule for the sensor that was set to far to the left on the metal guide rail. After reading your posts I remembered that a week or so ago, I reset the rule because the tone arm was no raising automatically at the end play on one of my records. The beginning set down and end point seem to vary depending on the record so I must have over adjusted the ruler.

Thank you again!

John

Hello Thomas,

Unfortunately I don’t have the technical expertise to advise you on this. But before I would trash it or give away the platter I would see if you could find someone to service it. Outside that non-working Beogram 8000 turntables still are worth abut on eBay. Someone else might be able to buy and fix it or use the parts to resurrect another nonworking one.

Hello All,

I just finished adjusting the tracking sensor on this Beogram 4002 and outside of polishing some scratches out of the dust cover I hope it is completed. Thanks to Mark and his help and encouragement I was able to get a few stubborn problems worked out. The 4002 was in beautiful cosmetic condition but had a severely frozen tonearm and a non-functioning board. I was lucky I was able to replace some components and not have some serious trouble shooting.

John

Hello Mark,

Thanks for the reply. So if the tonearm is angled towards the sensor arm when playing, does that mean it needs to be set to be more responsive?

John

- AuthorPosts