Glitch

Forum Replies Created

- AuthorPosts

-

I would expect about 0.7v forward and 2.7v +-0.1v in reverse (since it is a zener diode).

You might get a misleading reverse voltage reading depending on your tester. Testing with a series resistor, voltmeter and a power supply can be used to verify the reading.

Glitch

At this point I would just pull TR5, TR6 and D6 and test them. There is not much else to the RESET circuit if the voltages are all OK.

Glitch

quattttro: Do you have 5v on the secondary 5v circuit? If not, check the edge connections on the Microprocessor board for cracked solder joints, especially 2P2. Then check 2C65 and 2C2 for shorts.

Glitch

quattttro: I think I was able to prove to myself that the CPU was indeed dead. I ended up swapping the bad CPU into another BM6000 and the main issue followed the CPU. I still have a mystery to solve since the original machine does not work properly with the “good CPU” from the other machine.

Have you checked the 5v-cpu and 5v voltages on Board 2? Have you replaced 2R89 and readjusted the RESET circuit?

Glitch

My assumption was that you were experiencing something different than with your other/previous B&O receivers, otherwise you wouldn’t have asked the question. If there is an issue, there are multiple things that can cause a speaker thump.

Glitch

lollo: You might want to put a multimeter across the speaker outputs and check the DC offset voltage. This should be very close to 0.0V. Sometimes power-on “thumps” are normal/unavoidable, other times they are indicative of something else. It is hard to judge what you are actually experiencing from the information that you provided.

Glitch

I think the black line looks better. Now every time I see one of these I’m going to notice the seam ;-).

Could you put a piece of black electrical tape on the lip? That would give you the “black line” look and would be reversible if you don’t like how it looks.

Glitch

You guys are lucky. The closest B&O showroom to me is 300 miles away.

Glitch

I thought they may be connected on the trace but it would need to be confirmed with removing the board from the heat sink

You can verify the connectivity between points on the front side of the board by using a multimeter in the “ohms” setting.

Yep, the wire on the coax cable to the FM board is precarious. I had to repair this connection on all of the BM6000’s that I have. The trick for this repair is to remove the pins from the white connector for soldering and adding strain relief when reassembling.

Also, care should be taken to not jostle the light bulbs on the display board. The wires to the bulbs are very delicate/brittle. Just closing the “lid” hard from the service position can provide enough of a shock to break the connections.

Glitch

What ground do I use, the chassis, the removed connector, of the Mains ground?

For something like this, I setup the bench power supplies using a floating ground. I use multiple supplies (in series) to get the voltages needed. Googling something like “lab power supply grounding” will get you a better explanation than I can provide as well as providing safety tips and identifying pitfalls.

I am attaching photos of the different boards and spots. Am I correct, the error is on the PCB?

The markings on the PCB might be a bit misleading, but are actually correct. If you look carefully, the small resistor is connected to the large green one via the traces on the circuit board. Clipping the test leads on the green resistors is the most convenient location. The positive lead goes on the right resistor if I recall correctly.

Glitch

Test main power supply

- [PLUG OUT]

- Remove P41 & P42 from Board 16 and P34 from Board 9. Leave P40 connected on Board 16.

- [PLUG IN] Measure the 6.5v signal on pins 1 & 5 on P41. This may read high (~10v) since there is no load on it. Measure the 15v signal on pins 9 & 6 on P42. This should be very close to 15v. [PLUG OUT]

- Pull P19 on Board 6. Energize the rail voltage relay by connecting B16-P42-9 to B6-P19-8 and B16-P42-6 to B6-P19-10 (i.e. supply 15v to the relay)

- [PLUG IN] Measure the +50v and -50v rails at the capacitors. Measure the +32v signal at B16-P42-3 and B16-P42-9. This will also read high (~35v) since there is no load on it. [PLUG OUT]

- Reconnect P41 and P42 on Board 16. Leave P40 on Board 16 disconnected.

Test CPU power supply

- Remove P2 and P5 from Board 2

- [PLUG IN] Measure the CPU +5v on P5-1 and P5-3. This should be very close to 5.00v. Measure the +6.5v signal on P2-2 (it will still read ~10v) [PLUG OUT]

- Reconnect P2 and P5 on Board 2

- [PLUG IN] Measure the +6.5 signal on B2-P2-2. This should be close to 6.5v now. Measure the “other” +5v signal on B2-P2-3. This might read a few tenths of a volt high. [PLUG OUT]

Test Main Amp with Bench Power Supply

1. Connect to power supply

- B9-P34-1 -50v* * Start at about +-10v and work your way up

- B9-P34-2 GND

- B9-P34-3 GND (I can’t remember if pins 2 & 3 are connected on the board)

- B9-P34-4 +50v*

- B9-P31-3 GND**

- B9-P32-3 GND**

** The ground signals on P31 & P32 are not connected to the grounds on P34 on Board 9. I think B&O wired things this way to avoid a ground loop within the chassis.

2. Set power supply voltage to +-10v and the current to about 0.10A

3. Connect voltmeters to measure the Idle Current and Offset Voltage per the Service manual

4. [POWER ON] Adjust R110/R210 for an idle current “voltage” of around 5mV and R134/R234 for an offset voltage near 0.0v. The actual voltages are not critical now as long as they are below the 22mV and near the 0.0V that you are trying for at full voltage.

5. Increase the +- rail voltages in steps of say 10v at a time while watching the idle current and offset voltage and adjusting the trim pots as needed. You will need to increase to current limit as you go to about 0.3A

6. Work you way up to +-50v while keeping things in spec. [POWER OFF]

7. Wait for things to cool off to room temp

8. [POWER ON] Do a final adjustment per the service manual [POWER OFF]

At idle, all of my BM6000 draw about 0.19A on the -50V rail and 0.17A on the +50V rail.

For the light bulb wattage, I use a 150w bulb for most things. Other sizes should work as well. You won’t (hopefully) be drawing anywhere near the bulb rating since you aren’t trying to run the amp at full power. The bulb should stay very dim except when the the relay kicks on and the rail capacitors charge (it takes less than a second).

I just ran through the power supply steps on one of my BM6000’s to verify that I remembered what I did correctly. Please double check the procedures against the schematic (and common sense) to be sure that I didn’t make any typos, etc. The amp check-out procedure is from memory, so be more careful with that. Don’t hesitate to ask if it looks like I forgot a step or if my description isn’t clear.

BTW, I will sometimes hook up the main amp to a music source and speakers as part of the bench test. This can help provide confidence that all is well with the amp. It also saves the steps of install/remove if something else on the amp needs to be fixed.

Be sure to post results of your progress.

Glitch

A few months ago I did a similar project of getting several BM6000’s (that were put away “broken”) working again. I have a Variac, but didn’t bother pulling it out of storage for this project since I didn’t think there was much risk at destroying anything irreplaceable in the power supplies. However, when I did power-up the main supply, Board 16, I used a rig that has a light bulb in series. The order I did things was:

- Test the capacitors

- Test the main power supply (Board 16)

- Test the CPU power supply (Board 6)

- Test the main amp (Board 9) with a bench power supply. I brought the voltage up slowly with current limits in place. This is a good time to adjust the no-load current and offset voltage.

- Reassemble everything except the power connector to the main amp and test with the light bulb rig. It is hit or miss that the receiver will start in this configuration since the RESET circuit will likely trip.

- Test with the main amp power connected and the light bulb rig.

- Try power-up connected directly to the mains (only if step 5 & 6 looks good)

I recall that there was a signal or two that used the edge connectors as a safety circuit which kept the receiver from powering-up if the connector was off. These can be found by tracing through the schematics.

Glitch

In addition to the above suggestions, there is also the option for testing the various boards or subsystems separately. For example the power supplies can be tested with the other boards disconnected. The main amp can be tested using bench power supplies, etc.

My main goal in this situation is to avoid damaging parts that are hard or impossible to replace. For a BM6000, the microprocessor would be the main concern. Make sure that the 5v and 6.5v supplies to Board 2 are in spec.

I would also remove and test the large capacitors on the power supply before applying any power.

The “best way” to power-up an old piece of equipment depends a lot on your goals (how serious you are about preserving the machine) and resources (what test equipment you have to work with). For some people, all they need to do is plug the machine into an outdoor outlet if their main goal is simply not to stink up the house with electronics smoke ;-).

It would be easier for people to provide detailed help if you provide more information about YOUR goals and resources.

Glitch

Graham,

I usually try to start with pictures of the component side. There are often issues with the components blocking the board markings and sometimes depth-of-field. The trace side usually doesn’t have these issues.

For boards that are hard to get out… I just think of this as being unavoidable. One needs access to the trace side to do most repairs. I usually remove the board unless the board is really accessible. This helps with avoiding soldering mistakes that might damage the old, delicate traces. Also, often the boards aren’t as difficult to remove as it would initially appear.

Glitch

Graham,

I don’t have a layout diagram, but there are alternatives if you cant find one.

It is often easier to find a numbered component from the markings on the back side of the board. If the print is too small to read, the board can be scanned on a flatbed scanner and enlarged on a computer monitor. If you don’t have a flatbed scanner, taking a picture with a regular camera can also work. Once you have the board in digital format you can also mark it up in something like Photoshop or print it and add hand notes to the printout.

Glitch

after having spent decent money on BL90’s and a BS Theatre you’re satisfied with that solution?

That looks like something that I would do. Especially if I couldn’t find something that exactly met my needs. I’ve had some of these temporary/placeholder solutions in service for years until I found the perfect solution.

Glitch

Actually, Craig suggested that the issue lie in the mute circuit. I merely made a suggestion of how to prove or disprove his supposition. Also, if the problem wasn’t self-inflicted, the debug path that Martin was trying to lead you down WOULD have led you to the solution.

BTW, the issue was likely more related to the ESR of the capacitor than it being polarized.

Glitch

That one would have a higher value, likely 10uF. Can you confirm this?

Per the schematic, 5C15 is 4.7 uF.

I don’t have any other specific suggestions on what to try next. I will usually make enlarged copies of the relevant sections of the schematics and make notes on it (voltages, if something seems hot, etc.). I try to capture anywhere where B&O calls out a test point since if it was significant to the engineers at B&O, it is likely significant to me.

I would also recheck for cold solder joints and cracked circuit boards. Sometimes removing the board is the only way to be thorough. This also has the advantage in that one could take digital images of the board and inspect an enlarged image on a computer. I usually use a camera to take close-ups then stitch the images together to get a lot of resolution. I have also used a flatbed document scanner for this.

This might be a good application for using freeze spray? I don’t use freeze spray myself since I would rather debug using a FLIR camera. Maybe others can comment on this?

I’m still curious on what the actual voltage is on TP14 when the machine is cold and when it is warm and muted.

Glitch

When I mentioned 5C15, it was more of a rhetorical question relating to changing the type of capacitor in a circuit where the capacitor’s ESR might be significant to how the circuit operates. I see that there are other 1 and 2.2 uF capacitors in the muting and tuning circuits. Did you change these from electrolytic to film, or just the capacitors along the audio signal path? I’m not sure if it would make any difference in this particular case, but it might be a detail that could help explain things.

Glitch

Glad to hear that you are making progress…Capacitors were all changed into film caps

Does this include 5C15? Did you inadvertently change the timing characteristics of the silent tuning circuit?

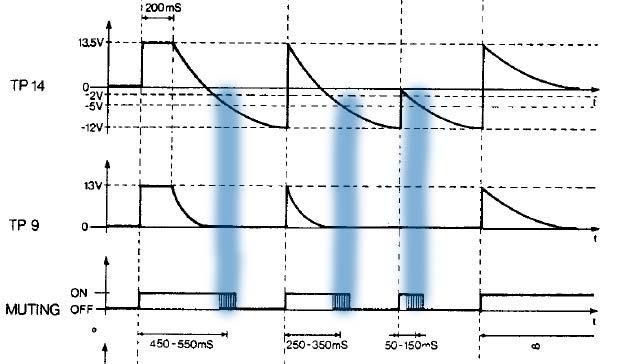

The figure showing the relationship between the TP14 signal and the Mute signal could be a clue.

TP14 moving into the range of -2v to -5v would partially enable the mute functionality.

I’m also very curious to hear if this is on just FM or also on the other inputs. I keep an old portable MP3 player on my bench as a source for doing quick tests like this.

Glitch

- AuthorPosts