Glitch

Forum Replies Created

- AuthorPosts

-

I didn’t find a specific reason for the overheating. The first step of this Beomaster repair was to remove the circuit boards and inspect them under a stereo microscope. I like to make repairs to any “mechanical issues” (i.e. cold/cracked solder joints, cracked boards, solder bridges, etc.) before applying power for the first time. I recall fixing what appeared to be shipping damage, but my notes are sketchy. Unfortunately, the quantity/quality of my note-taking can be inversely proportional to my excitement about working on something and I was pretty stoked about digging into the project. 😉

I did take a few pictures of the more interesting discoveries.

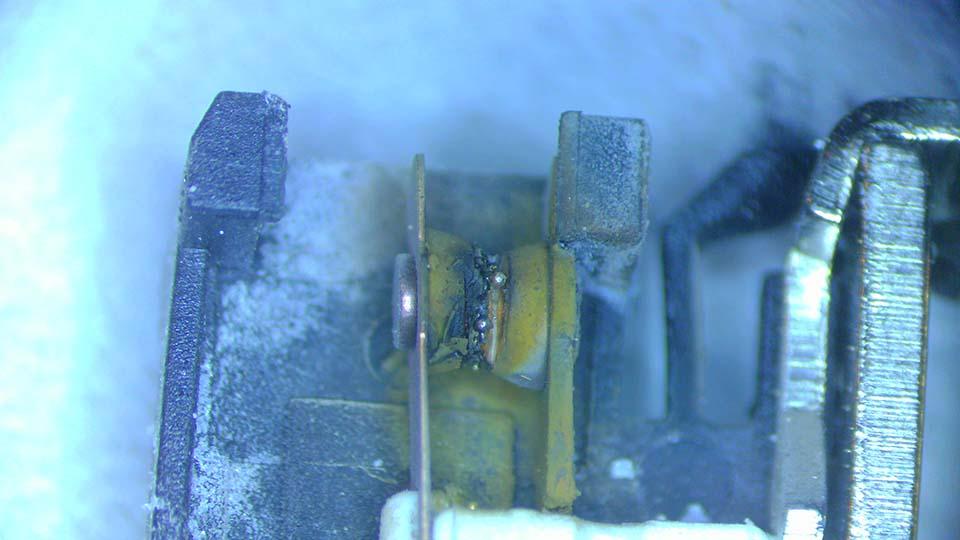

Power relay contacts

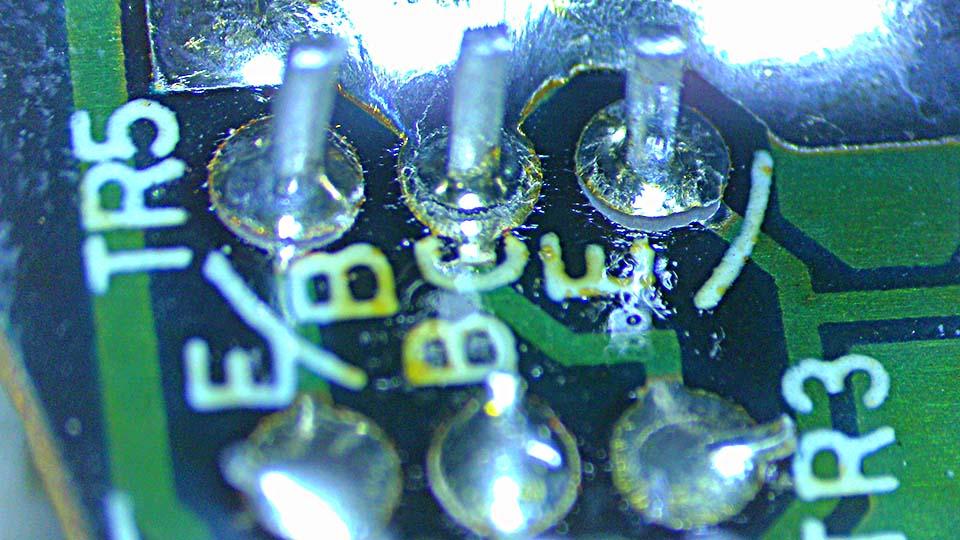

Broken solder pads on fan control board.

The Beomaster is running at “as expected” temperatures. Warm, but not hot enough for the cooling fan to engage.

Glitch

I spent some time researching and working out a way to send such a fragile piece, and I think I have found a good solution. I will custom make the boxes which should be able to withstand international shipping. The aim was to make a box that doesn’t compress or twist and which weighs less than 1kg in total to make shipping more affordable.

I like the box. Very neat. A minor improvement would be to add some support between the ends of the “U” (i.e. make it structurally more like an “O”). This would reduce the chance that the plinth breaks due to its own mass during a hard impact.

I’m always a bit surprised by how brutal shipping can be. When I pack something for shipping, I imagine it being dropped off a moving vehicle, then sat on by a toddler. 😉

Glitch

Check the metal braces on the underside of the upper cover. The plastic “rivets” that connect the brace to the cover can fail. This lets the cover interfere with the drawer. Also check the screw for mounting the drawer motor. This can rub if the drawer rollers have settled.

Glitch

A very timeless and complete set in my eyes.

Thank you for the kind words.

I think that the styling of the 5500-7000 series has aged quite well. One of my goals is to get B&O equipment into the “public rooms” at my son’s house. My daughter-in-law can be pretty selective about the decor. So far, she has only agreed to a Stage, but I think she is warming up to other options.

It must be hard to go back to a lightweight plastic remote after getting used to a Audio/Video/AV terminal.

Glitch

I am considering doing something similar, my colleagues are highly recommending I just go all-in and remove the dust cap and do it properly.

I always consider the likelihood that I could remove the dustcap and residual glue without damaging the cone. Finding a suitable replacement dustcap is sometimes a problem. I like to install a slightly larger dustcap than what I removed to help hide any evidence that the driver was worked on. This is usually pretty straightforward with woofers, but I’m not so confident with something like a Penta midrange.

Another thing to consider with dustcap removal and shimming is that uneven tension of the surround/spider will undo any shim alignment as soon as the shims are removed. Obviously, drivers with tighter tolerances will be more sensitive to things like this.

One idea that I’ve had is to use a combination of techniques. Combine the segmented clamp/gluing concept with using an inspection scope (stereo microscope) to visually check the coil alignment. I haven’t tried this yet, but will when I have the need to service something that requires high precision.

Glitch

Evan,

I use something similar to clamp the surround. Depending on the particular driver, I’ll run some tests with just the clamp. Once I’m happy with the performance, the surround gets some glue. Sometimes, a segmented clamp is needed so that the surround can be glued a section at a time with a thin needle applicator syringe.

I’m not too surprised to hear that much of this is being done by hand. I’m guessing that the difference between the higher and lesser quality parts has to do with the “end of line” testing and sorting.

Glitch

What these tests do not offer are acoustic responses. To test the spectral capability we would need to measure on a baffle with microphones etc. To really understand uniformity, we would need to both Klippel and mic several samples to understand the consistency.

My (possibly bad) assumption is that if two drivers are similar mechanically (displacement response, driver shape, etc.) and electrically (impedance vs frequency, etc.) that they will be similar acoustically.

I think that many people underestimate how easy it is to do a “suboptimal” surround replacement. I’ve found some drivers, especially ones with tight tolerances, can be very finicky to get right. I’ve been able to pick up differences in alignment techniques (centering, foam tension, etc.) with the relatively crude measuring equipment that I have.

Some people make it seem like refoaming is always trivial. Maybe they are right (and I am just not very good at it), but I think it is more likely that they aren’t testing their work. It reminds me of something that happened at work. We had a group of developers that kept reporting that they “hadn’t found any bugs in their software”. I eventually figured out that statement was their way of saying that “they never tried testing their software”. 😉

I’m looking forward to seeing any test results that you are willing to share…

Glitch

Cool. I appreciate seeing data even if I don’t understand exactly what it is saying. 😉

Is the testing a driver easy enough where it is possible to test multiple drivers?

I’d be curious about the driver uniformity, especially the refoamed mid-ranges. With some measure of “sameness” you could either pick the best of the batch for your project or sort for best matched pairs.

Glitch

I absolutely loved it and would really appreciate any help in identifying said components / machine.

Here is a nice website that has pictures and dates for B&O equipment. This page may be the best one to start on: https://beocentral.com/receivers

Once you have identified the product, https://www.beoworld.co.uk/products.asp can be used to find more detailed information about it.

Glitch

and no – you currently can’t have two Theatres playing in sync in a multichannel (i.e. one-room) system.

That’s disappointing. I was looking forward to the “Beosound Theatre Innovative Configurations” thread (i.e. the Theatre version of the “BeoLink Converter 1611 Innovative Configurations” thread) 😉

Glitch

Ralph,

Looks good and like it was meant to be there.

BTW, I saw in another thread the suggestion to use a small bolt and nut to create an attachment point. This would be an easier way to do the same thing.

Is there enough adjustment to be able to set the “needle down” position correctly?

Does your sliding chassis park without any chatter?

Glitch

Actually, my question was more like towing one car behind another ;-).

Something like this but with Theatres 😉

The towing situation is possible for some car combinations, but not for others.

Glitch

How about a “pair” of Theatres?

I know that this isn’t practical, but I’m curious if the software could handle this. (Hopefully this question isn’t too off-topic)

Glitch

My best guess is that it that the post is glued on, breaks off easily, and gets lost. I wonder if B&O originally designed something that fit into the hole but changed their minds?

Please post pictures of whatever you make to fix the problem.

Glitch

Ralph,

Yes, it definitely looks like you are missing the post where the spring and string connect to the sliding chassis. It initially looks like the post is molded as part of the sliding chassis frame, but on a closer look I’m not so sure. Here is a picture from the bottom of the sliding chassis.

There appears to be a seam there. This is a strange design choice.

I suspect that you will have a hard time finding just the post. You may have to buy the whole sliding chassis frame. Alternatively, you could make a new custom post that fits into the existing hole. Maybe something like a piece of threaded rod that screws into the hole with part of the rod shaped to form a new post?

I still have not fixed the chattering issue. I moved on to other projects hoping that someone already knew the solution and was willing to share.

Glitch

I got my BL4000’s running. They had multiple issues including a bad standby transformer, fried relay, and foam rot corrosion. The corrosion not only dissolved some of the traces but also broke some of the connections between the SMD lead and the SMD component body. It was a challenging debug for all of the wrong reasons. 😉

I have a solution for the standby transformer that uses readily available parts. However, there are some (possibly safety related) caveats associated with it. Send me a PM if you are interested in the details.

Glitch

The latest (and last for now) Franken-MMC (FMMC) experiment. The donor cantilever is aluminum with a conical, bonded diamond stylus.

My cursory evaluation of the cartridge performance on a 1 to 20 scale, where 1 through 5 map to B&O’s MMC1 through MMC5, respectively, and 20 is something put together from sewing needles and twigs…

The FMMC with the $2 pink ceramic stylus is about a 17. The grafting is relatively easy to do, but the playback is muddy and suffers from distortion on some recordings.

The FMMC with the conical, bonded diamond stylus is about a 12. The playback distortion exhibited by the pink ceramic FMMCs is gone. In general, the highs and lows are there, but the fine detail is not. It sounds like a tired, inexpensive cartridge. This isn’t surprising since it actually IS a tired, inexpensive cartridge.

My overall conclusion is that this type of DIY grafting isn’t very practical. There is a learning curve where one will certainly destroy some donor cantilevers and/or target cartridges. The overall performance could certainly be improved upon by buying a higher quality donor cantilever/stylus. However, the risk/reward ratio just isn’t there. Botching just one reasonably nice donor cantilever and having to replace it puts the overall price in the ballpark of a new SMMC4 (that has a fresh suspension).

My future plans are to use the grafted cantilevers for evaluation of cartridge suspensions. I have a handful of cartridges with missing cantilevers. I got these with various used turntables and have no idea of their history. If I happen find a suspension that still has life in it, I’ll be remotivated and graft it. Maybe some sort of nude elliptical?

Yep, none of this made sense. Wound I do it again? In a heartbeat!

Glitch

Burned-out standby transformers seem to be a pretty common problem for B&O speakers of that era. The transformers in my BL4000’s appear to be a bespoke part, only having B&O markings and no markings from the supplier that produced them. Based on the prevalence of identical failures, the part was poorly designed, but well manufactured (at least from a repeatability standpoint).

What is interesting about this particular failure is that a failed transformer still outputs a random voltage. This is why you still see the red light, which is pretty robust to voltage variations. The green light is more sensitive to the actual voltage value, so this may or may not work with a failed transformer.

I’m interested in hearing if anyone else has a already has a solution or knows of a replacement part. My research didn’t find much beyond people ordering a replacement part/board from B&O. I assume that that particular pile of parts is long gone.

I’m currently working on an alternative solution, but it is going slowly. Maybe one of the transformer candidates that come in with the next parts order will be a winner. Please let me know if you make any progress and I’ll do the same.

Glitch

my beomaster 7000 is humming. What can i do ?

Teach it the words? 😉 (sorry, I couldn’t resist)

Seriously though, it would be helpful if you could provide more information about the specific setup and/or conditions where you are experiencing the hum. Does it sound like 50/60Hz? Is it coming from the speakers or the chassis?

Glitch

Any ideas?

In addition to what Martin said…

Are you doing your powering-on using a “dim bulb tester” (or equivalent)? If not, you might want to. This would reduce the possibility of doing more damage while you sort things out.

Glitch

- AuthorPosts