Dillen

Forum Replies Created

- AuthorPosts

-

Not totally correct. The rl140 used foam surrounds, and the rl7000 rubber surrounds. If you compare the crossover they are the same. But the rl60 has a passive membrane and the rl60 w has a bassreflex. Im gonna refoam my rl140’s with rubber you and not with foam. If the flexibility for both surrounds is the same, just take the most durable ones…lesser sensitive to temperature and moist fluctuations. Ok

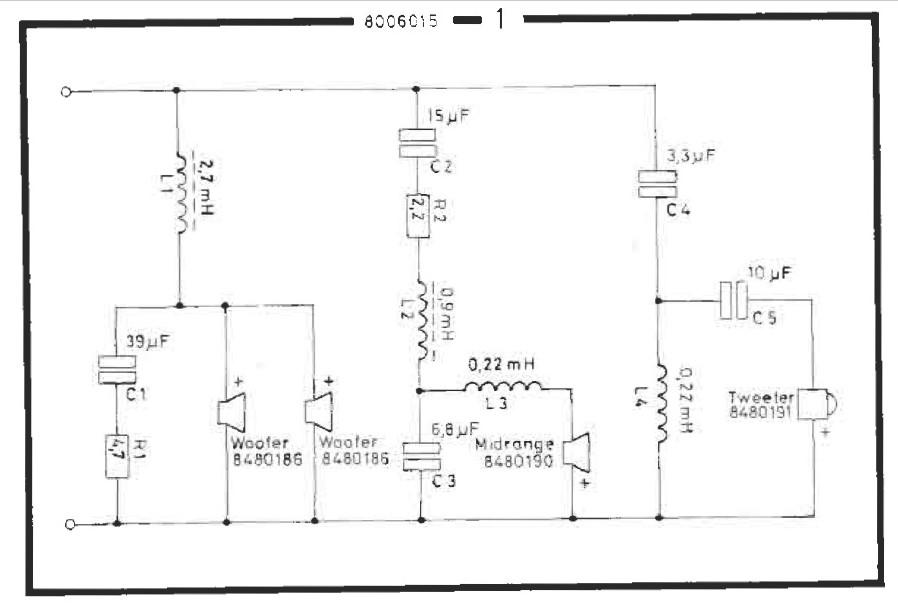

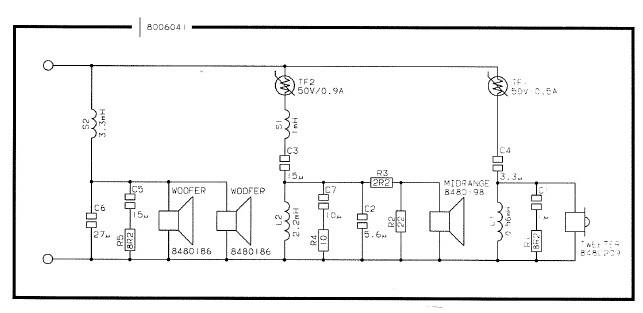

Beovox RL140:

Beovox RL7000:

The woofers are identical. The rest – not quite, I think.

The woofers are identical. The rest – not quite, I think.Rubber may last longer (or it may not, depending on the type of rubber),

but if you measure the drivers T/S parameters and compare foam and rubber, you will

be surprised to see how much of a difference it makes.

In some cases it will end up an almost completely different driver.

I would stay with foam where foam was originally used.And keep in mind to let newly refoamed woofers play for some hours before judging/comparing.

They will almost always be a little stiff and sound a bit “stubborn” or “tame” at first, and they will need to losen up a bit to do their job as intended.And don’t compare to how they sounded with the old, partly disintegrated foam, as having the woofers cones flapping around undampened and

uncontrolled, as they would be, will also be far from what was intended with T/S parameter readings everywhere and nowhere.Martin

Beoworld neither can nor will provide a pin code, and neither can anybody else, sorry to say.

It’s part of Bang & Olufsens anti-theft programme.

Best is to bring the original purchase receipt with you to the nearest dealer, but

as a minimum bring the unit in with the serial number intact and visible, so they

can check against B&Os stolen goods registry.

If everything is fine it won’t take long for them to reset the unit.If it’s stolen, it’s worthless.

Martin

These decks have very few problems with lubrication, really.

Unless something is not working as it should, there is really no need to do anything.Martin

Shorted 1C53 (220uF)?

Martin

If the cone of the woofer has seized solid (common problem), it can usually be repaired with a little skill.

Before the new forum took over the old forums URL you could look up guidance and tips for repairing your woofer. Several threads in the old (archived) forum discussed and showed how.

Now you will be lucky if google comes up with anything usable.But, basically, it’s a matter of manipulating the magnet and the pole piece.

Martin

A small amount of teflon-based “oil”.

A seller on Ebay once had something called “liquid bearing”, that’s very good.

Because it’s not really an “oil”, but mainly microscopic teflon balls, it doesn’t really

evaporate and it doesn’t grab and hold dust and dirt the same way an oil will.Don’t use shaver- or sewing-machine oil. It evaporates over hours rather than years, and

most will leave some of its additives etc. behind.Forget WD40. Keep that in the garage for use with rusty cars.

Martin

So was I.

Martin

Check the three large filter capacitors.

Martin

It’s my impression, that Multicare is one of the best places, you can send your Beogram.

The trim will be replaced as part of Bang & Olufsens Classics Recreated programme to reflect that, after 50+ years, it was rebuilt professionally.

(Using good quality parts).I wouldn’t worry.

Martin

Blown fuse and/or ripple on power supply DC voltages from bad filter capacitors (the three large cans).

A scope will tell.Also, if present in your Beocenter, check the capacitor on the edge of the CPU board. It’s known to short.

Martin

I doubt you can find someone selling parts for this particular model, but many electronic components are fairly standard.

Which parts specifically are we talking about?Martin

The two screws can be accessed from below at an angle, through holes and passing boards etc.

Martin

If you are sure the belt is correct and not something off Ebay or similar, lubricate the motor bearings.

Martin

Check the motor phase adjustment.

Martin

When in 45RPM, does the motor pulley vibrate if you feel with a finger, or is it completely still?

Martin

Perhaps a bad capacitor somewhere. That wouldn’t be a first.

Put a scope to the signal path, compare left/right and see, where the signal is lost.Martin

Use a puller.

Grab under as close to the spindle as possible, not to bend the copper plate.

It’s easily distorted.Martin

Grease won’t do.

It has to be an oil, and it has to be light, homogenic and “self-dissolving”, and of course have the right properties and additives.

A mix of primarily SAE30 was used originally.The bearings from Beoparts are pre-oiled, ready to fit. So are the felt washers.

Just clean the spindle using IPA and a clean lint-free cloth.

And then keep the spindle clean. Leave no fingerprints on it afterwards, – there is no room for any.With the motor reassembled, you may need to align the spindle and bearings axially, or one or both bearings may end up running on “edges” instead of parallel on their plain inner surfaces.

Originally there was a tool for this task (not a very good one, really) but moving the spindle

around, pushing it sideways a little and rotate it by hand, paying attention to

the run-off time, will give you an idea of the sweet spot.Martin

Perhaps not that exact product, but I know a thing or two about sinter bronze bearings,

and I have had my hands on lots of things with names beginning with “super”.

I remember one product was advertized for use with space shuttles, for which I’m sure it will be fine.

But I threw most of it away. It didn’t do anything near what I wanted it to.

Now I think of it, perhaps it was because I didn’t have a space shuttle to use it with.Anyway, – if it has teflon or similar modern “floating”/”suspended” stuff, that gets pressed in to the pores in the

bearing material, cluttering them, it’s usually safe to deem it no good for sinter bearings.

And very difficult to remove from the bearings pores again as teflon and microplastics are not easily dissolved. At least not without leaving a mess behind.Martin

- AuthorPosts