Die_Bogener

Forum Replies Created

- AuthorPosts

-

The MMCx cartridges sound depends very much on the weight or load. 0,8gramm to 1,5gramm, depending on its construction. You can play with the load…

… or get a good libra.

The RIAA is also important. Some use filter caps on the input side against noise. This is not good. You have a schematic?

For music you dont need more than 2 good speakers. Any speaker more makes it worse.

Music and something like Dolby 5.1 is not working. It sounds great some hours and then you notice: there is something wrong. Even if it was recorded in Dolby, you will hear the difference, it just takes some time … and then you will sell it or scrap it.

For TV it doesn’t care, there is no music, just noise… bumbumrattatatabigbadabooom

This may not matter if the 8000s have no significant output at those frequencies anyway, to phase-cancel.

Your ears will notice the difference that there is something wrong. Be sure, you can hear it. Maybe not today, but in some weeks…

And if you know that there is something wrong, you can hear it. Everytime, everywhere … 😉

Why not a quite normal Beolab 2 ?

The delay will only be compensated when you sit straight inline… TV-BL8000-Bl19.

If you sit in different locations not inline you will hear the delay.

Are you sure, that the powerlink socket is a output for other speakers and not input?

It is no good idea to mix analog speakers with DSP driven digital speakers, there is always this disturbing delay. Playing with the runtime of the signal is only suitable for one (small) position in the room where it sounds right. All other positions notice the difference in runtime … distance and DSP runtime.

Why not using a quite normal analog bass?

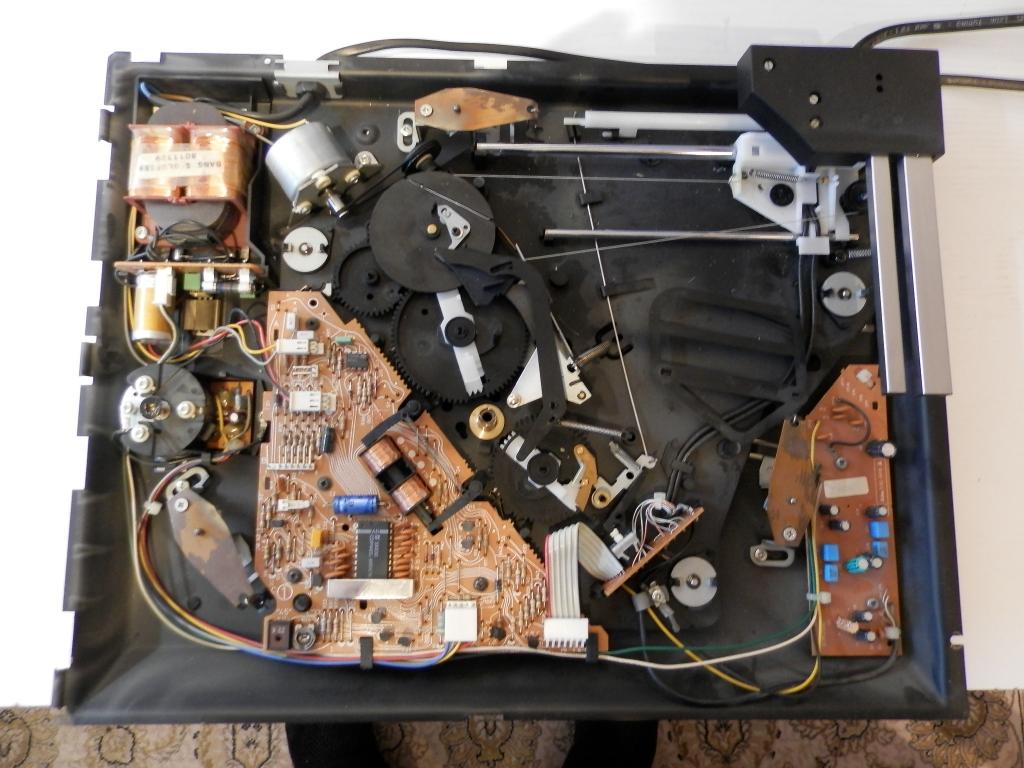

New belts are sometimes not ok, some have to much tension and are too small. Sometimes the tension is so high that the drives moves to the left side.

Too much tension also stresses the motor and needs to much power, the motor can not regulate it any more and makes “wowow”…

The right tension is very low, just test the belt that it does not work like chewing gum… getting bigger and bigger.

A good belt is stiff and keeps it’s size and dimension, not like a rubber band or chewing gum…

It is not a good idea to plug in power, having a red led and then connecting Powerlink. Can make a big PLOPP and then nothing in the future…

Has it ever worked before, did you see or hear it or bought defect?

The gear does only the movement, the head has it’s own justage … see the red stuff? This is for the head position.

The gear should only be in something symmetrical end position when switching side 1 – 2

I think there is one tooth wrong… just 1 tooth in endposition looks a little bit weak overlap… how does ist look in the other position? 3 Teeth?

There is not one fixed position… there are 2 !

It’s an “either or” position. The spring shall fix it in side 1 or side 2.

It’s an over the peak snap construction.

Just snap it in the gap next to the teeth…

Ebay?

L272M N8 around 50 offers, especially in GB. ~ 5-8$

BD437 is ok, 45V instead 35V… will work.

OK, safety resistor was dead…

Then the LM272 control of the motor can also have a problem.

There is a safety resistor R1 4,7 Ohms in the power supply for TR1… i have seen this defect already several times…

If there is a mechanical overload of the drive it will blow. Especially if the motor is bad… check the motor on a regulated supply. There are caps INSIDE the motor… at least in the BC5500 drive, 7000 i dont remember right now…There is no 22V AC… it’s just 22V DC unregulated. And if in standby without load there can be more than 28V? Maybe, should be ok.

Since it should be the same keyboard foil with 8×5 keys and quite the same layout: 2300 and 2500 should use the same foil. Even BS9000 and Overture should use the same.

That means, that a scrab BS2500 could donate the foil for your BS2300 if the service part is no longer available… 😉

@Guy: Thanks for the PDF, it confirms that there should be the same keyboard foil in all of these Beosystems…

It’s just a matter of cleaning the keyboard… above and behind. It’s a matrix of lines and colums… so a line is not working.

Probably some liquid came behind on the contact board… or a corroded plug of the front/display, may be cpu/lithium battery.

Remove the glas and covers, dismount the front and clamper, disconnect the wires, remove the keyboard and clean it with alcohol. Otherwise replace the keyboard… usually including front, easier…

Do you have access to a datalink connection?

I had a 8032 cpu with a defect INTerupt pin… meaning that IR is working bad. I connected the master to a MX TV-set… and all was working fine. Exchange of the cpu and the master was ok.

But: use a good socket. It can happen again. The reason is a missing z-diode on the INT pin, causing a small overload during communication. I added a 5,6V z-diode…

And: check the keramic caps near the connectors. There were problems with them, mechanical stress is not good for them.

Also the connector on the front-IR board is very often corroded, causing erratic flickering of the display data.

Martin 2

Siemens, Philips, Intel are OK.

ATMEL is not ok. To modern…

It must be a standard 80C32 CPU, not with extra additional ram… just 256 internal Bytes. No additional Eprom or ROM or extended RAM beyond 256bytes. No extra Timer.

Not Atmel 80C32x2 because faster…

I prefer Philips, just because of asian counterfeits… intel and Siemens are more expensive or some people get more of your money for nothing.

Martin No.2

The cpu is a 80C32 chip. Jep, there are still a lot of them available… but most are not compatible with the old one.

It must be a Philips 80C32 BPN (!!!)

Not compatible are 80C32x2 … they are working faster, there are timing problems.

Have you checked 5V on the cpu board? Best point is the Eprom 27512… Pin14 GND and Pin28 5V.

Was there a Service RESET done… if battery changed? (!!!) Otherwise it will not respond!

BL8000: the standby transformer T2 has something like 2W available. Usually this transformer is very, very often defect of heat… and the power board is very rare. Usually found for 200,- replacement… if found. And used ones are not in good condition…

If the BT needs 5V 0,8A the transformer will not survive some hours… the transformer can supply 150mA in total. I had to replace last month a dozen of them … and new transformers that fit to the board are very rare and hard to get… out of production for 15 years.

There is plenty of room inside the BL8000 to install a quite normal PSU switch power supply in the upper loudspeaker area…

This one here was burning after 20 years…

Hi,

taking fotos is a very good idea. Documenting with fotos before and after the operation… i do it also before beginning a difficult repair or a unit without documents…

Did you pull any connectors, plugs or something like that? Is it possible to assemble them the other way round? Or shift it by a pin…? Or forget a connector? Pins can break in the solder pad…

Blown fuse?

Disconnect the repaired drive and remove it, a center should also run without it and start again.

Good luck!

Martin

Hallo Ernst,

das BC9300 hat dieselbe Radio Platine wie BS2500 und Overtüre. Baugleich jeweils pro Empfangsland…Diese Platinen habe ich dutzendweise instandgesetzt, es sind immer wieder dieselben Kandidaten: Elkos. Nach 20 Jahren ist einfach Schluß und das wird auch mit 30 Jahren keinesfalls besser.

Als besonders auffällig habe ich die kleinen 47uf in Miniaturgröße empfunden, aber das ist schlicht egal. Tausche alle, man kann nicht genau sagen welcher Kandidat defekt ist. B&O hat für jeden einzelnen Schaltkreis/Baugruppe jeweils einen Ladewiderstand und einen dieser 47uF Elkos verwendet. Fällt er aus, zieht er jeweils eine Baugruppe ins Nirwana.

Gruß

Martin

- AuthorPosts