Transit protection device in Beogram 1203

Tagged: Beogram 1203 bushing

- This topic has 5 replies, 2 voices, and was last updated 12 months ago by

Knutte.

- AuthorPosts

- February 26, 2024 at 11:09 am #30368

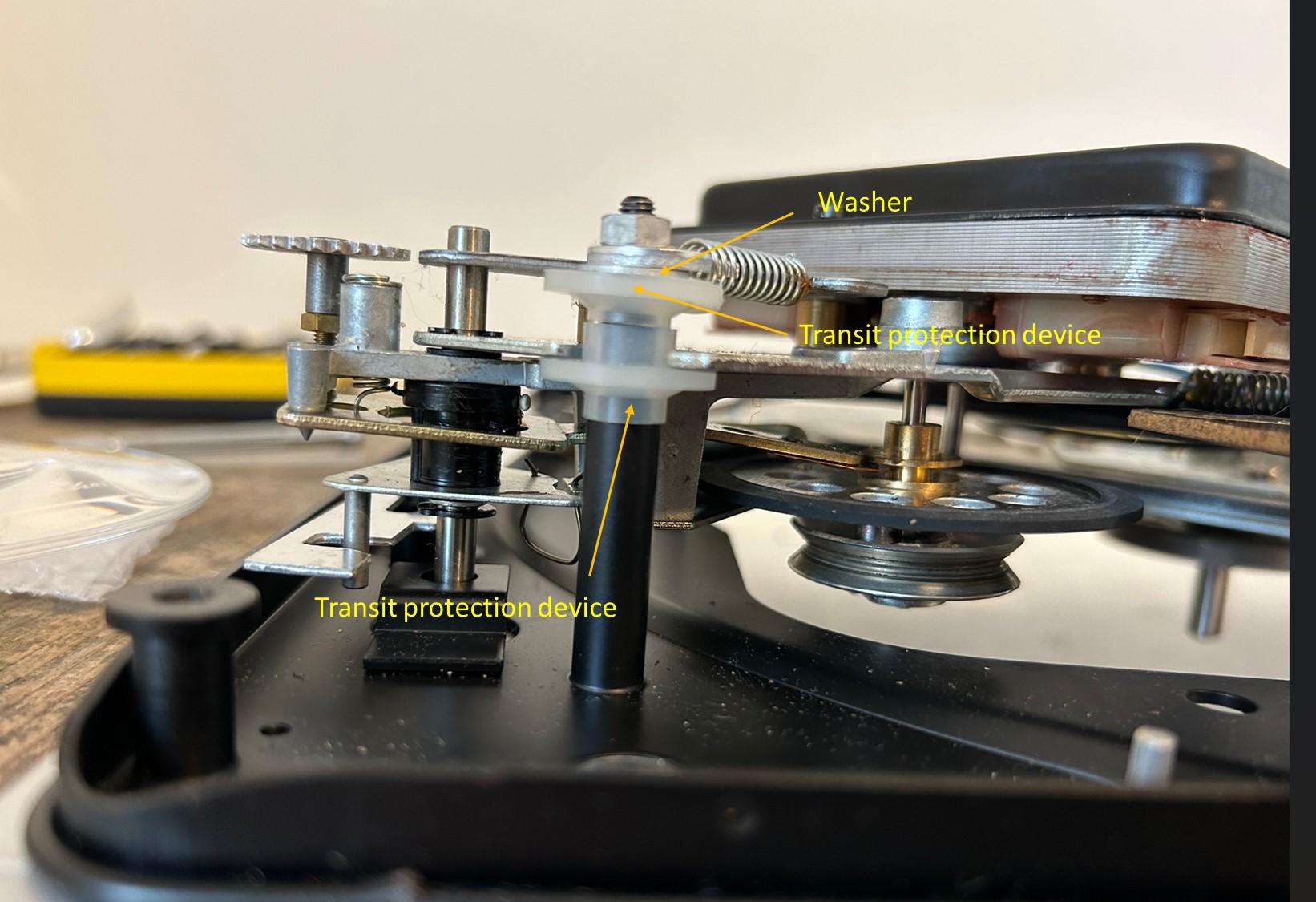

I’ve replaced the motor bearings and the idler wheel of my beogram 1203. Now when I try to re-assemble I realize the #38, “transit protection device”, 2938075 and #41, “transit protection device, 2938076 in the 1203 service manual are not the same. I can’t tell from the service manual diagram which one is which. Also I’m afraid I’ve ended up with an extra washer when I’m done. Could anyone please tell if I’ve placed the “transit protection devices” in the correct order and with the correct orientation. Also if you could please offer any hints of where the additional washer might come from.

Thank you in advance!February 26, 2024 at 2:17 pm #30374The important thing is that the motor bracket is free floating, and its

metal “ears” will not touch the nylon bushings (or you will hear rumble/whirring/running noise).

If, when you have put it all together, and the deck is in its normal upside up position,

the metal brackets are close to the bushings, you could try swapping the two bushings

and see if it ends up better centered.There can be a washer under the nut as well.

Martin

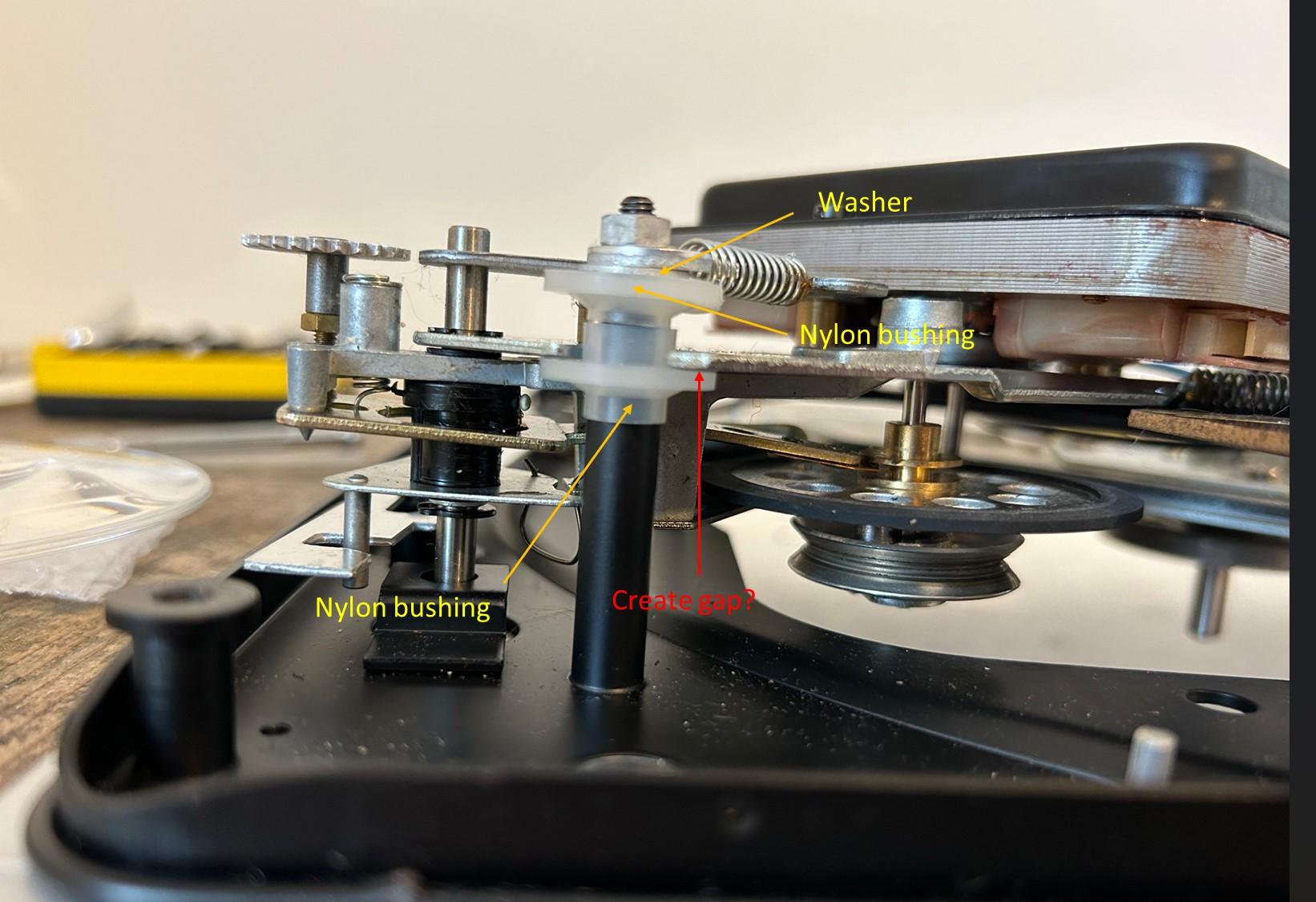

February 26, 2024 at 2:50 pm #30375Thank you Martin. Don’t know why the service manual calls them “transit protection device”, maybe something lost in translation. However, do I understand you correctly, I should make sure that there is a gap between the nylon bushings and and the motor bracket, indicated in red below? I did indeed hear running noice when I turned it on.

February 26, 2024 at 4:54 pm #30382

February 26, 2024 at 4:54 pm #30382Yes, that’s correct. Both sideways and up/down. The metal “ears” mustn’t touch.

And it should be when the deck is upside up (not upside down as in your photo).The bushings are actually for transport safety, because the heavy motor would be free to

swing around pretty wildly in transport, if they weren’t there to limit its movements.Martin

February 26, 2024 at 5:17 pm #30384Thanks a lot again Martin.

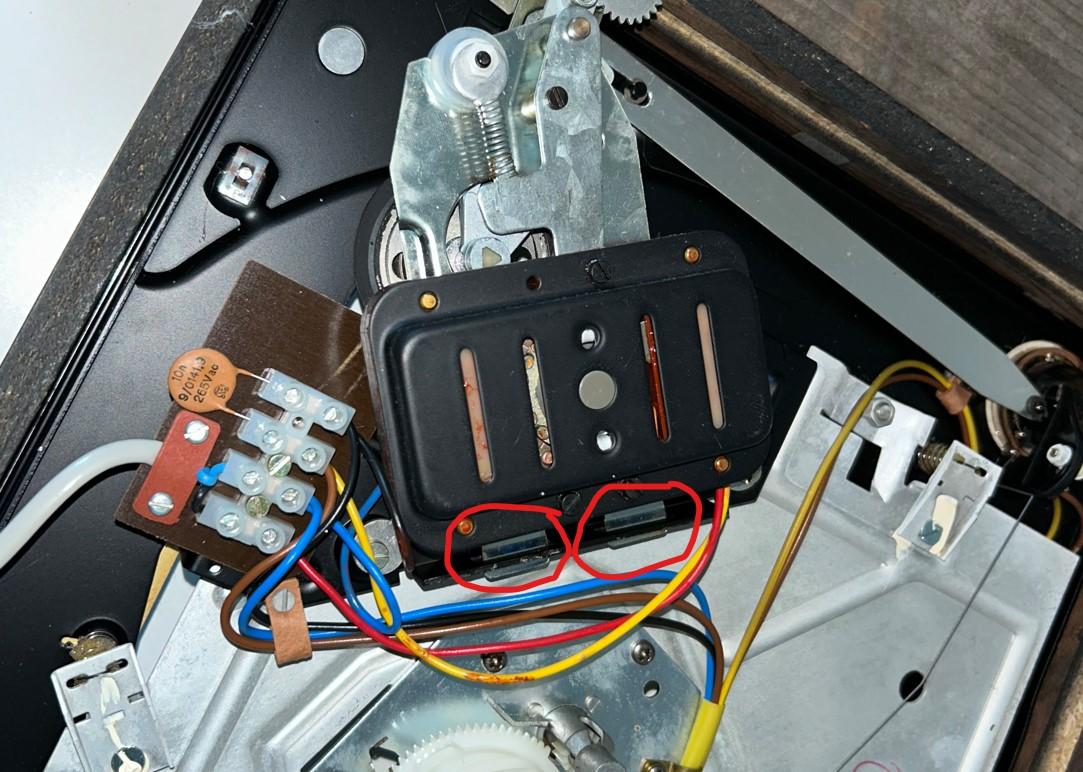

Ok, I understand. What about the ears that are on the other end, in the slots in in the chassi, see below, should they also be free flowing?

Once, thank you so much for your help./Fredrik

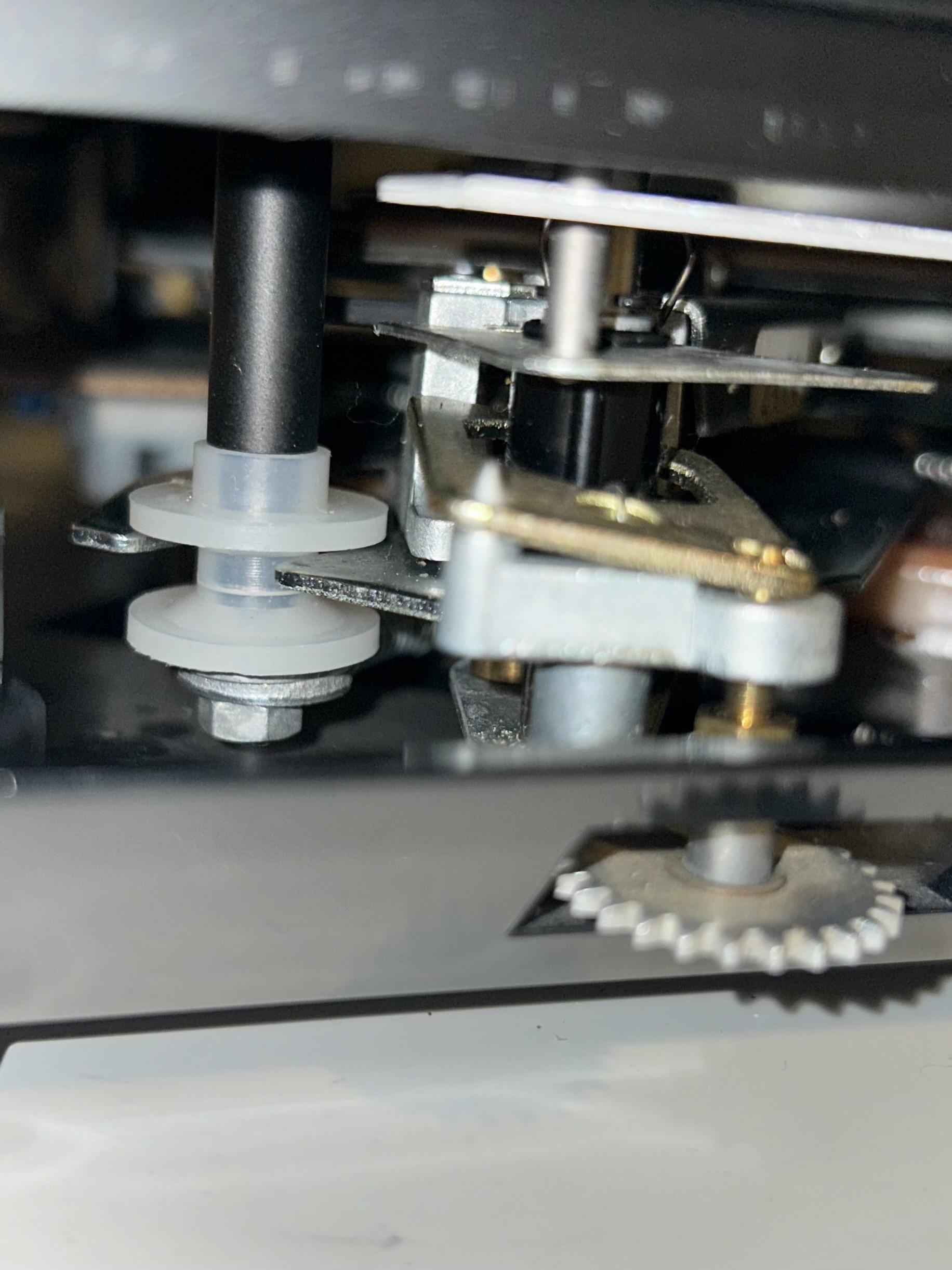

February 27, 2024 at 12:56 pm #30412I made yet another try at orienting the nylon bushings and was able to get rid of the noice. Success! I assembled without the wooden frame and was able to verify that the motor frame didn’t touch the bushings. I took at photo and will leave that here for the next person experiencing the same problem.

Thanks again Martin!

Thanks again Martin! - AuthorPosts

- You must be logged in to reply to this topic.