Beocenter 9300 Laser replacement

Tagged: Beocenter 9300 Laser

- This topic has 6 replies, 4 voices, and was last updated 1 year, 4 months ago by

Madskp.

- AuthorPosts

- October 16, 2023 at 8:54 pm #24961

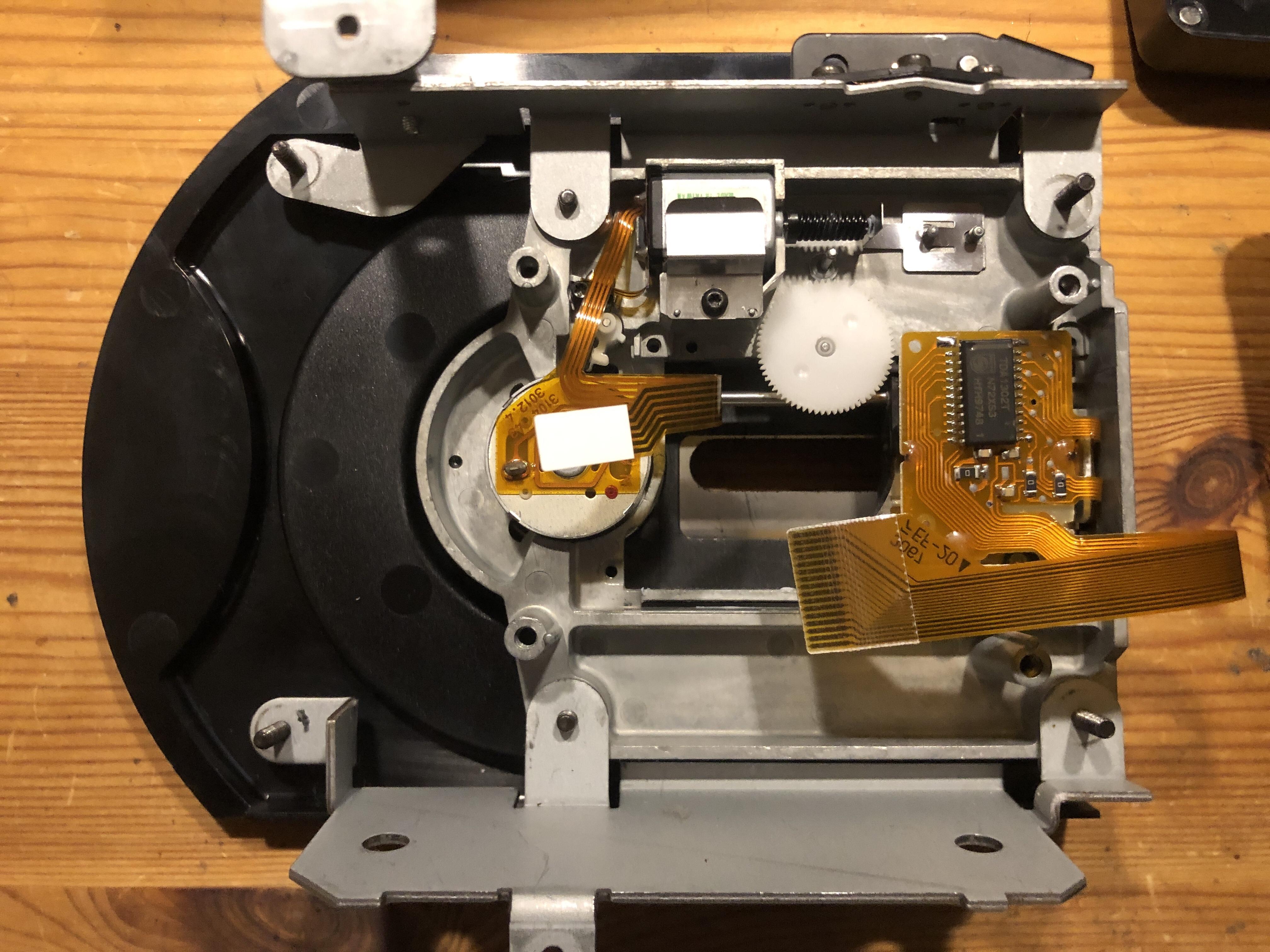

Got a replacement laser for the Beocenter 9300 and now trying to replace it, but cant for the life of me figure out how to get the old laser module out.

To me it looks like I have to remove the big white gear to be able to lift the guide rail and the laser module out. But I can’t make the gear move out, and a little afraid to break it.

Any inputs?

Thanks in advance

October 18, 2023 at 6:16 am #24981Hi:

Watch this video:

Go to 5:45 mark.

Derek

October 18, 2023 at 6:27 am #24982And use ESD-protection!

These things are highly sensitive to static electricity.

Many owners experience that new lasers don’t work, – and while it is correct that

many asian “counterfeits” won’t work, or only work for a few hours, many lasers

are damaged by static electricity, – either during shipping, if shipped without

shorting clamp and/or ESD-shielding or by handling without taking

proper ESD-precautions.

I have seen many of both cases.Martin

October 18, 2023 at 12:09 pm #24992Hi: Watch this video

Go to 5:45 mark. DerekHi and thanks for the video link. It seems though that on the unit he is working on in the video he is removing a plastic bracket which gives acces to the other guide rail. But on the on from the BC9300 that both the guide rail and the overhanging “bracket” is part of cast metal, so there is no way to get the laser module up in that side of the mechanism.

As I see it the only way is to remove the white gear, but I am very open to other suggestions

October 18, 2023 at 12:11 pm #24993And use ESD-protection! These things are highly sensitive to static electricity. Many owners experience that new lasers don’t work, – and while it is correct that many asian “counterfeits” won’t work, or only work for a few hours, many lasers are damaged by static electricity, – either during shipping, if shipped without shorting clamp and/or ESD-shielding or by handling without taking proper ESD-precautions. I have seen many of both cases. Martin

Hi Martin and thanks for the warning. I have a grounded antistatic mat and wristband ready so I hopefully won’t fry the new module in the proces

October 18, 2023 at 1:25 pm #25001The white gear wheel is just snapped on the axle. Either pull it or use a small needle to open the snap…

October 19, 2023 at 12:35 pm #25020The white gear wheel is just snapped on the axle. Either pull it or use a small needle to open the snap…

Succes. It just needed the right amount of force to come of. Thanks for the tip. Always great to know beforehand if use of force is a good idea or gonna break think.

Installation of the new laser module vent smooth and now the CD part of the BC9300 is running smooth again ?

Thanks to everyone for inputs

Next up is changing belts in the casette deck

- AuthorPosts

- You must be logged in to reply to this topic.