Beocenter 8500 – Cassettedeck stopped working

- This topic has 20 replies, 5 voices, and was last updated 2 years, 4 months ago by

Die_Bogener.

- AuthorPosts

- June 25, 2022 at 6:21 am #6143

Hi all,

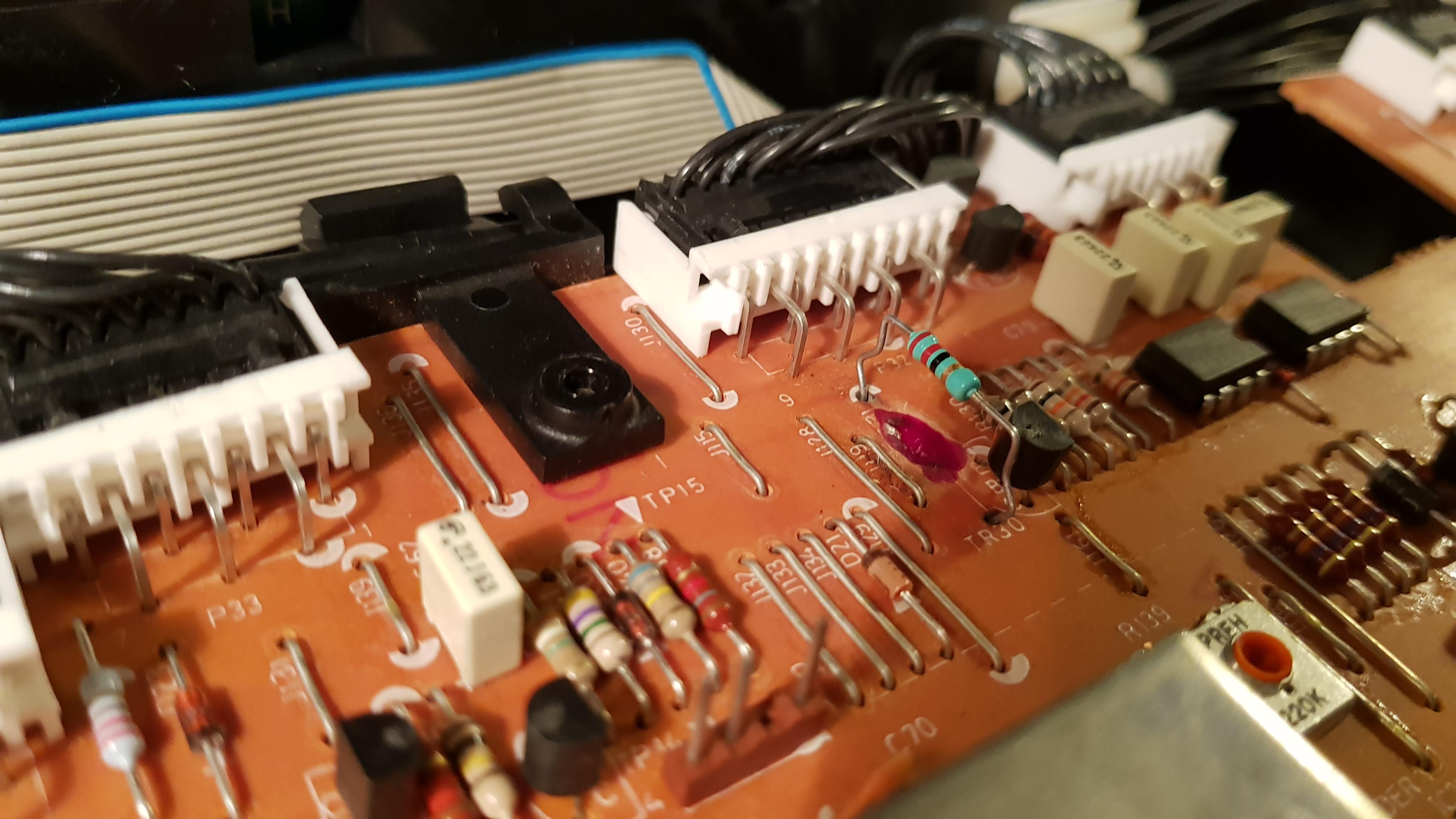

This is my primary Beocenter in the living room. Suddenly the right speaker cut out, I repaired the mute relay and presto there is sound again. Then I thought let’s spin a cassette as I had aquired some nice prerecorded ones. All is fine, cassette spins and music comes out nicely when suddenly: nothing.

Symptoms are that, when a tape is loaded and play is pressed, the play array comes up. This is good. But that is it. Nothing moves. If I repeat this process without a tape in it I can see that the right take-up reel moves slightly back and forth (a notch).

I thought I could smell something burning, no smoke or anything. Just that smell. So, off the unit goes and onto the workbench (again). I can’t find anything that is actually burned on any pcb (I would expect a burned resistor). Nothing seems out of the ordinary.

Tape belt is intact but likely a bit too slack. That said it worked before without a hitch on the same belt. I haven’t ordered a new belt just yet because I need to work out if the deck can be saved first.

Any ideas if this is mechanical (in the tape deck) or electrical?

Thanks!

BB

June 30, 2022 at 7:38 pm #6330Hi BB

Hardly could remember but there was a kind of smell in a Beocenter 9500 came from Resistor R131 on Board No. 20.

The PCB was burned, scrached it all away and coated it with some Nailcoating from my wife ( be quiet don´t tell her ;-))

It´s a 22 Ohm Resistor and in my opinion the resistor should limit the Current through the Motor.

As in your case there was nothing wrong with the belt or drive, mounted a new Resistor on “higher legs” so the PCB is not blackened anymore. Mounted a new belt, Member Dillen has the right ones, don´t buy somewhere else some work some don´t, belts from Dillen working always.

Hope you´ll have success

Kind regards

Christian

July 2, 2022 at 2:16 pm #6426Hi Christian,

I’ll be damned, exactly the same resistor is burned to a crisp on mine. I’ll replace it with one that can handle a bit more power. And i’ll also put it on ‘legs’. I have a Beoparts belt which is the best I know, so i’ll put that on as well.

Let me see if this will fix the issue :-).

Bert

July 2, 2022 at 2:53 pm #6429Hi Christian,

replaced the resistor but unfortunately no success. When I load the tape the array comes up and then flips itself (direction change) and then disengages. It never starts to run. Fast forward and reverse are fine so it’s not the new belt.

Something must have bitten the bullet when the resistor died in flames. Oddly I can’t find any transistors that are dead in the water in the circuit.

Bert

July 3, 2022 at 4:59 pm #6461The resistor in question is in series with the motor and is there to allow the safety circuit to monitor the motor current.

A too high current will cause a high voltage drop across the resistor (that’s ohms law), again causing the

monitoring transistor to issue a signal to the tape controller to stop the drive (in some Beocords/Beocenters take it into standby).

The resistor will also double as a safety fuse in severe cases, so DON’T fit a higher wattage resistor unless you want a house fire!The resistor is not the problem – it merely indicates a problem.

Check the motor in the tape drive – seized?

Check the reel tables – seized?

And if the drive is the one-belt type, check the small idlerr at the extreme corner of the drive – seized?

Take apart, clean and relubricate accordingly.

Finally, check the power supply voltages – is the motor running at all?The resistor is not marked as a safety component in all manuals, but it really should be.

Fit a good fusible (or at least flameproof) type of resistor.Martin

(Apparently there is no longer a member called Dillen).July 4, 2022 at 5:37 am #6485Good morning Martin,

Yes the burning resistor is indicative of a larger issue. I replaced the resistor with a 250mW metal film resistor, it should be fine. The rest of the mechanism is all ok, nothing seized and has a new Beoparts belt. It is a one belt drive. It was playing fine when suddenly it slowed down pretty fast and then stopped altogether. This coincides with the burning resistor.

But. It seems there is no power going into the drive. The motors in there are fine, I can turn them on external power, nothing is seized. This must be the reason why the drive isn’t spinning. At least the capstan motor isn’t getting any juice at all. I expect the other motor to be down as well (I’d rather not muck around with that one even on low external voltage because it drives a lot of gears.

I need to check these B&O schematics on where the power to the motors is actually coming from and if there are any dependencies on that.

Bert

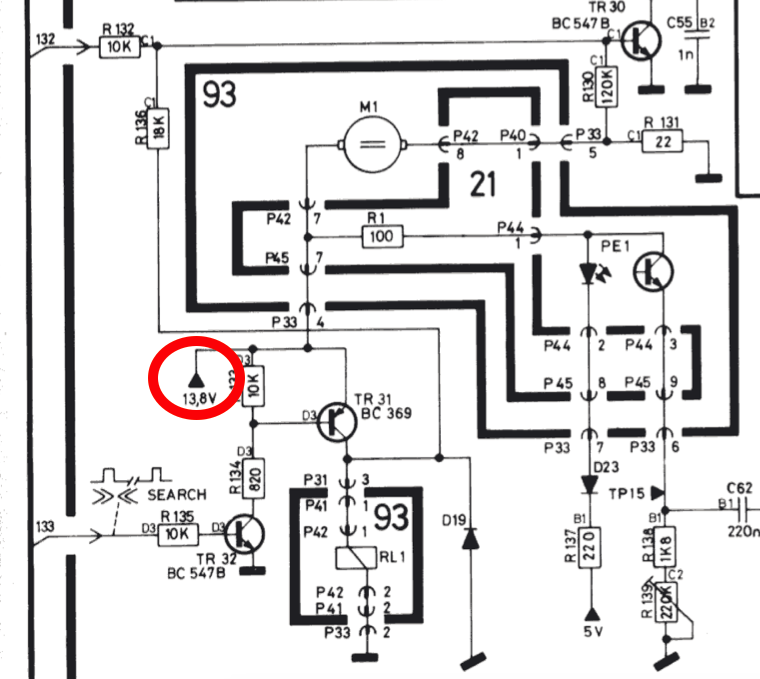

July 4, 2022 at 6:06 am #6486Hmmm. The main motor should get 13.8v when engaged but is getting 0v.

As is usual with these B&O schematics I can’t find where this 13.8v is coming from. It just magically appears in the schematics (see the red circle).

BB

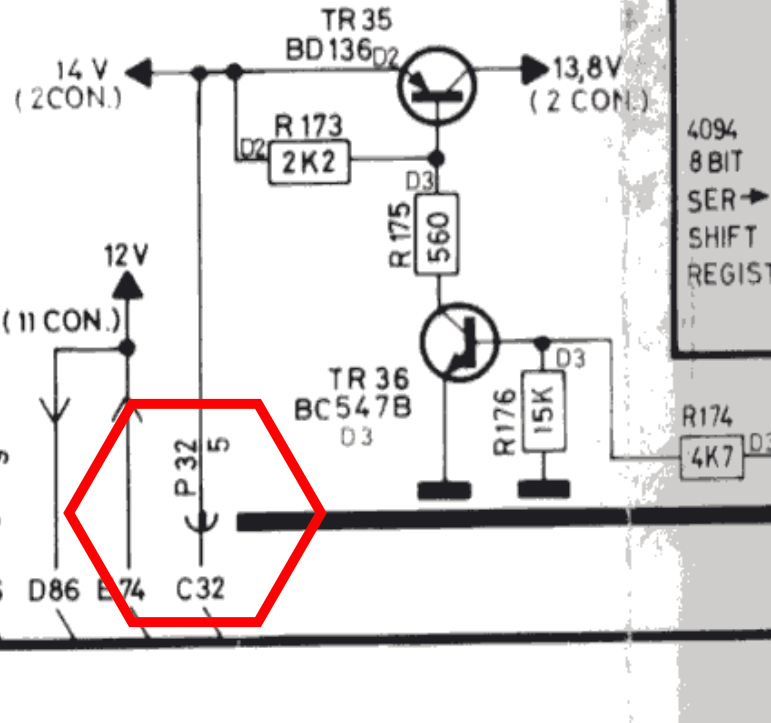

July 4, 2022 at 7:27 pm #6515I tried tracing the 13.8v line. In the end it comes to a connector which is called C32 in the schematics. Sadly that line can’t be found anywhere in the schema. I really, personally, hate B&O schematics. They are always so damn faultridden and overcomplicated. That said I expect that line to lead to a voltage regulator or something that is busted because there is 6v on the input line. Not 14v as the schematics show. Now where to find that doohickey……

July 4, 2022 at 8:21 pm #6516

July 4, 2022 at 8:21 pm #6516The connection is named C32, which means that it can be found on diagram C with number 32.

On diagram C, it is named F32 because the connection goes to diagram F.

Nothing strange about this.

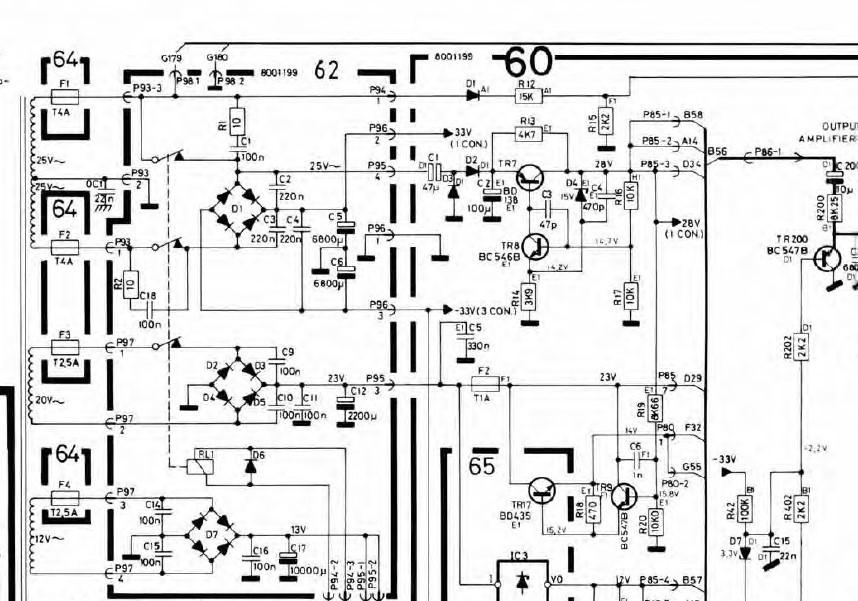

In other words TR17, C12 and F2. Check for cracked solder joints.

Martin

July 7, 2022 at 5:48 pm #6606sorry it is very busy over here. TR17 was busted, replaced it with one from stock but that did not solve the issue. I need to analyse this further as it seems there has been a cascade somehow. That BD435 would not blow quickly at all.

- The voltage regulator (IC3) is good.

- The 2200uF cap is also good.

- F2 fuse is good

Need to trace the entire path again even though I did not find any that were clearly broken.

Bert

July 8, 2022 at 7:18 pm #6656Hmmm. TR9 which is connected to TR17 was also busted. On replacing the transistor it immediately blew when power was applied (through a variac). There appears to be a short somewhere, I need to check if TR17 survived this. The power supply before the fuse is fine, all voltages are good if C12 (2200uF) was bad it would have killed the 12v power regulator as well (but it is fine).

So it has to be something downstream. The motor is good, I can apply just 4v DC and it spins without a hitch. I can move the two reel tables (I think that’s what they are called) by hand, no issues. There is a small motor on the backside of the tape assembly, this also works fine.

I have checked all of the transistors in the chain leading to the motor in the schematics and can’t find anything out of the ordinary. Only near the power supply are 2 blown transistors of which one blows immediately after replacement.

I need to think about what the hell is happening here. Cascade like this is not normal.

Bert

July 9, 2022 at 12:27 pm #6674TR9 (BD435) is fine. So it seems that the TR17 is where the problem ends. I need to think about this because I just can’t find anything wrong. Desoldered all transistors in the pathways to be sure, they all test fine. F32 transistors also all fine. No shorts. So why this transistor blows in such a simple circuit when not even full power is applied is a mystery at the moment.

Suggestions are very much welcome 🙂

BB

July 9, 2022 at 6:03 pm #6677Desolder/remove TR17.

Use a seperate power supply and send 14V with limited current instead TR17… and check wether there is a short in the system or why it needs so much power.

Dont blow some transistors, use a regulated power supply instead. Try less than 14V and limitied current…

July 10, 2022 at 4:26 am #6680Okay check, no problem. I’ll start with injecting about 2v as I would see a current draw far above what is reasonable already. Can always ramp up the voltage a bit at a time.

Thanks!

BB

July 11, 2022 at 4:55 am #6707Okay, I think the problem is mechanical. I’ve setup the system in such a way that the power is all external. When I press play the left reel spins but the right one does not (see image). This would put undue stress on the lowly BC547 causing it to burn. Likely as a protection for the BD435.

Now my question is: how the hell do I dismantle this deck? Is there anything in the way of a ‘tutorial’? It doesn’t seem to be all that easy and mucking around in B&O decks is a sure way to never having a working deck again.

Many thanks!

BB

July 11, 2022 at 5:00 am #6708Also, I am wondering what the hell actually happened. The deck was playing fine for some 30 minutes. Then it started to slow down and eventually stopped, causing a cascade blowing the two transistors and burning the resistor. I have this hunch that more is going on here than just a bit of lubrication.

Bert

July 11, 2022 at 9:01 am #6709Hi Bert

You mentioned the small Motor on the back, please check if the plastic gearwheel is tight fit to the motorspindle, had already two which were cracked and slipped through / did not really turn the other gearwheels completly, so the drive got stuck in some unusual state, sometimes worked sometime only fast forward and so on.

If cracked you could glue it back in place with superglue, worked fine both times.

Kind regards

Christian

July 11, 2022 at 10:28 am #6711Remove the black cover… 4 bolts on the backside.

Remove the small plastic c-ring on top of the wheel.

Clean with alcohol isopropanol. The grease can be very sticky…

July 14, 2022 at 9:02 pm #6774Hi all,

sorry for the late reply. I have an eye disease and sadly I am sudenly almost blind.

I was able to repair the Beocenter by dismantling the entire cassette mechanism and relubing it all. Now with the replacement transistors it is all working fine again. It is likely to be my final repair 🙁

Many thanks for all the help,

Bert

October 4, 2022 at 11:44 pm #9453i have a question. and wondered if you’d seen the same. on the underside of the tape deck the belt on the smaller white capstan is constantly in contact with the large aluminium wheel.

Also these seem to be going all the time and never stopping even if playing the radio.

thoughts? Thanks

- AuthorPosts

- You must be logged in to reply to this topic.